How to Use Capsule Filling Machine: Semi to Fully Automatic

Due to an increase in production demands, manual capsule filling is no longer enough for many operations. That’s why semi-automatic

Finetech offers a wide variety of automatic capsule filling machines for different applications, from pharmaceuticals to the food and cosmetics industry. We have been customizing and supplying this innovative equipment for years, making us a reliable one-stop-shop for such solutions.

Automatic capsule filling machines are incredible tools that fill and seal empty hard gelatin capsules with powders, liquids, or granules. They are versatile, consistent, high-speed, and accurate. We offer the following top-notch automatic capsule filling machines:

Weight: 800 kg

Maximum output: 24000 capsules/hour

Noise Level: ≤ 75dBA

Control System: PLC control with touch screen and frequency conversion control

Motor Power: 1.87kw + 2.2kw (Dust Collector)

Weight: 1000 Kg

Maximum Output: 48000 capsules/ hour

Noise Level: ≤ 75dBA

Motor Power: 3.7 KW

Weight: 985 Kg

Maximum Output: 72000 capsules/hour

Noise Level: ≤ 75dBA

Motor Power: 5.57 KW

Weight: NJP 2000 (1300 Kg) and NJP 2500 (1350 Kg)

Maximum Output: NJP 2000 (120000 capsules/hour) and NJP 2500 (150000 capsules/hour)

Noise Level: ≤ 75dBA

Motor Power: NJP 2000 (8 KW) and NJP 2500 (9.5 KW)

Weight: 2400 Kg

Maximum Output: NJP 3000 (180000 capsules/hour) and NJP 3200 (192000 capsules/hour)

Noise Level: ≤75dBA

Motor Power: 9.37 KW

Weight: 2500 Kg

Maximum Output: 336,000 capsules/ hour

Noise Level: 80 dB

Motor Power: 7.37 Kw

Weight: 4200Kg

Maximum Output:432,000 capsules/hour

Noise Level: <75DB(A)

Motor Power: 13.58kw

| Model | Weight | Max Output | Noise Level | Motor Power |

|---|---|---|---|---|

| NJP 400 | 800 kg | 24,000 capsules/hour | ≤ 75 dBA | 1.87 kW + 2.2 kW (Dust Collector) |

| NJP 800 | 1000 kg | 48,000 capsules/hour | ≤ 75 dBA | 3.7 kW |

| NJP 1200 | 985 kg | 72,000 capsules/hour | ≤ 75 dBA | 5.57 kW |

| NJP 2000 | 1300 kg | 120,000 capsules/hour | ≤ 75 dBA | 8 kW |

| NJP 2500 | 1350 kg | 150,000 capsules/hour | ≤ 75 dBA | 9.5 kW |

| NJP 3000 | 2400 kg | 180,000 capsules/hour | ≤ 75 dBA | 9.37 kW |

| NJP 3200 | 2400 kg | 192,000 capsules/hour | ≤ 75 dBA | 9.37 kW |

| NJP 5600 | 2500 kg | 336,000 capsules/ hour | 80 dBA | 7.37 kW |

| NJP 7200 | 4200 kg | 432,000 capsules/hour | ≤ 75 dBA | 13.58 kW |

Automatic capsule filling machines can handle a variety of materials, from pellets to powder, granules, and even liquids. Due to their amazing speed, precision, and consistency, automatic capsule filling machines are used in

Capable of filling thousands of capsules within an hour without any consistency issues.

High-speed and accurate filling

Intuitive PCL and high-quality touch-screen display that allows easy operation and parameter adjustment.

Touch-screen display

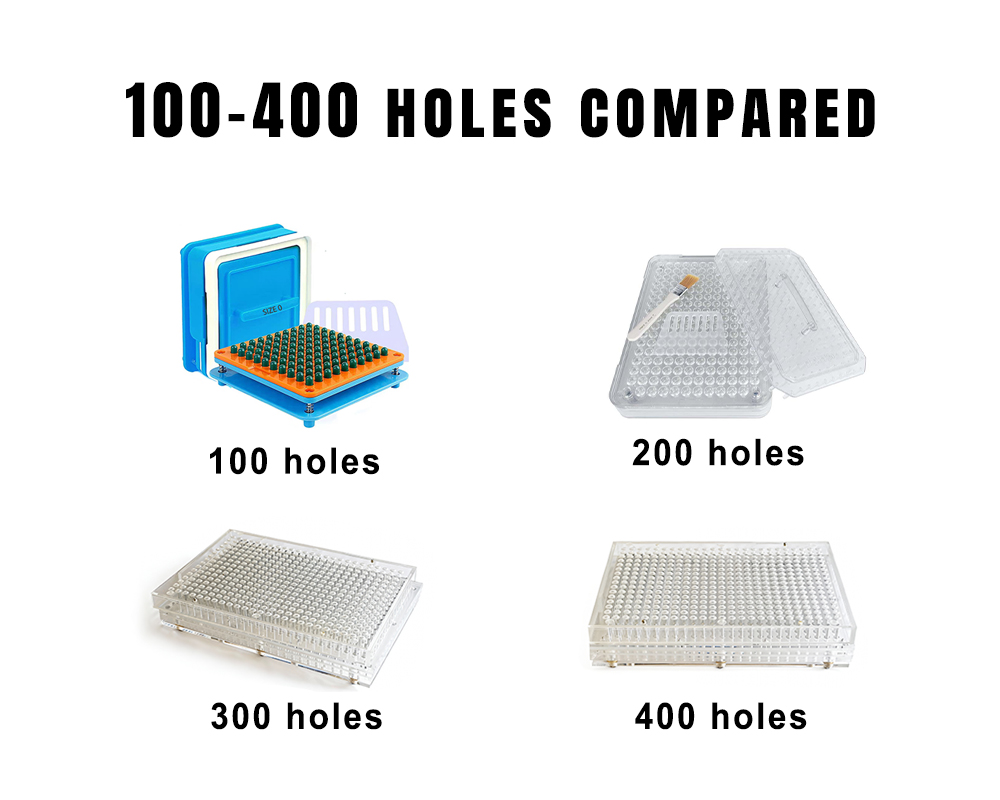

Easily handle a huge variety of capsule sizes from 00 to 0.5 for diverse applications.

Wide capsule sizeThe working of our auto capsule filling machines is smooth, so even beginners can get their hands on them. It’s a simple multi-step process that involves:

This covers a wide range of knowledge about capsule filling equipment, including maintenance standard operating procedures, purchasing advice, supplier recommendations, and working principles, etc.

Due to an increase in production demands, manual capsule filling is no longer enough for many operations. That’s why semi-automatic

Filling capsules by hand can feel intimidating at first, especially if you have never used a capsule filler before. Powders

Standard Operating Procedure of Automatic Capsule Filling Machine 1.0 OBJECTIVE: This SOP walks you through operating the Automatic Capsule Filling

When you’re thinking of scaling capsule production, the machine you choose can make or break your workflow. Whether it’s a

Yes, all our automatic capsule filling machines come with 2-5-year warranties, which gives you the necessary peace of mind. But we must according capsule filling machine parts to Evaluate

Yes, our machines can handle different types of capsules, including Gelatin and HPMC.

Automatic capsule filling machines can handle versatile materials including powders, granules, and pallets.

Yes, our automatic capsule filling machines offer high precision and a filling accuracy of + and – 2% to 3% ensuring consistency in dosage.

Yes, most automatic capsule fillers are made to comply with GMP and CE requirements. They are designed to handle sensitive products such as pharmaceuticals and food items.

The typical safety features of automatic capsule filling machines include emergency stop buttons and automatic shutdown whenever there’s an error.

Yes, most parts of our automatic capsule filling machines are made of stainless steel, which is easily removed and cleaned.

Yes, it’s necessary to train operators on the usage of automatic capsule fillers to make sure they operate and maintain the equipment properly.

yep!

check here

We are suitable for capsule sizes 000#-5#. Please refer to the capsule size chart for details!

WhatsApp us

Feature photoelectric detection systems and other safety mechanisms that detect issues in the capsule filling machines and shut them down to avoid severe damage.

Advanced safety mechanisms