How to Use Capsule Filling Machine: Semi to Fully Automatic

Due to an increase in production demands, manual capsule filling is no longer enough for many operations. That’s why semi-automatic

We provide semi-automatic and fully automatic capsule filling machines, fitting capsule sizes 000, 00, 0, 1, 2, 3, 4, and 5.

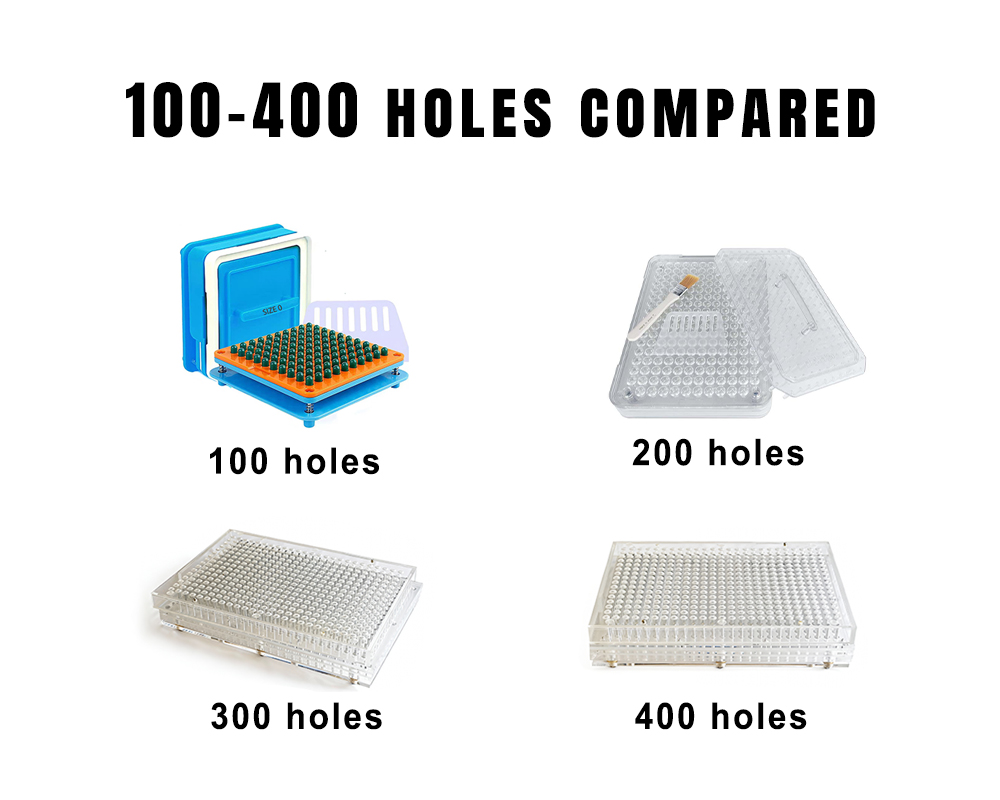

A manual capsule filler is a simple, non-electric device used to fill empty capsules with powder or herbs quickly and consistently. It typically consists of a set of plastic or metal plates with precisely sized holes that hold capsule halves in place.

This is a hot-selling 100-hole capsule filling machine applied for capsule sizes 000-5, widely used in home DIY, laboratories, hospitals and small-scale manufacturing enterprises.

This is an acrylic manual capsule filling tray that can be customized according to the holes number and capsule size. The MOQ is one piece.

The semi-automatic capsule filler is a cost-effective, user-friendly machine designed for small to medium-scale production of capsules (gelatin, HPMC, or vegetarian). It combines manual loading with automated counting and filling, improving efficiency while maintaining affordability.

Max. Capacity: 25,000-30,000 pieces per hour

Applicable capsules: #00, #0, #1, #2, #3, #4, #5/Different size need different mold

Packing size: 1800x1200x1700 mm

Max. Capacity: 25,000-30,000 Pcs/hour

Applicable capsules: 000#, 00L#, 00#,0L#, 0#, 1#,2#, 3#, 4#,5#

Power: 4.0 kW

Packing size: 1140×700×1600 mm

Max. Capacity: 40,000 pcs/h

Applicable capsule: 000# /00# /0# /1# /2# /3# /4# /5#

Power: 2.2 kW

Packing size: 1640*720*1700 mm

A fully automatic capsule filler is a high-speed, precision-engineered system designed for large-scale pharmaceutical, nutraceutical, and supplement production. It automates the entire capsule-filling process—from capsule separation and filling to sealing and ejection—with minimal human intervention.

Weight: 800 kg

Maximum output: 24000 capsules/hour

Noise Level: ≤ 75dBA

Control System: PLC control with touch screen and frequency conversion control

Motor Power: 1.87kw + 2.2kw (Dust Collector)

Weight: 1000 Kg

Maximum Output: 48000 capsules/ hour

Noise Level: ≤ 75dBA

Motor Power: 3.7 KW

Weight: 985 Kg

Maximum Output: 72000 capsules/hour

Noise Level: ≤ 75dBA

Motor Power: 5.57 KW

Weight: NJP 2000 (1300 Kg) and NJP 2500 (1350 Kg)

Maximum Output: NJP 2000 (120000 capsules/hour) and NJP 2500 (150000 capsules/hour)

Noise Level: ≤ 75dBA

Motor Power: NJP 2000 (8 KW) and NJP 2500 (9.5 KW)

Weight: 2400 Kg

Maximum Output: NJP 3000 (180000 capsules/hour) and NJP 3200 (192000 capsules/hour)

Noise Level: ≤75dBA

Motor Power: 9.37 KW

Weight: 2500 Kg

Maximum Output: 336,000 capsules/ hour

Noise Level: 80 dB

Motor Power: 7.37 Kw

A capsule polisher is a machine used in pharmaceutical manufacturing to clean and polish capsules after they have been filled.

semi-automatic capsule filling machine is a cost-effective, user-friendly device designed for small to medium-scale production of capsules (gelatin, HPMC, or vegetarian). It combines manual loading with automated counting and filling, improving efficiency while maintaining affordability.

FTP-110A is a newly designed Capsule Polisher to polish capsules and tablets, it is a must for any company producing hard gelatin capsules.

The JFP-110A is designed for pharmaceutical factories, healthcare product companies, laboratories, and food processors. This multi-function machine features a compact body, easy operation, and a high degree of automation.

Read the latest knowledge about capsule filling equipment, including SOP, operating principles, and manufacturer list recommendations……

Due to an increase in production demands, manual capsule filling is no longer enough for many operations. That’s why semi-automatic

Filling capsules by hand can feel intimidating at first, especially if you have never used a capsule filler before. Powders

Standard Operating Procedure of Automatic Capsule Filling Machine 1.0 OBJECTIVE: This SOP walks you through operating the Automatic Capsule Filling

When you’re thinking of scaling capsule production, the machine you choose can make or break your workflow. Whether it’s a

Manual (300-1,000 caps/hr): Hand-operated, requires loading each capsule

Semi-auto (1,000-10,000 caps/hr): Machine fills but requires manual tray loading

Fully auto (30,000-200,000 caps/hr): Complete automation with minimal human intervention

Standard machines handle sizes 000 to 5. Or you can check our capsule size chart!

Powders (most common)

Granules/pellets

Micro-tablets

Liquids (with special attachments)

Semi-auto: ±3-5% variation

Fully auto (GMP): ±1-3% variation

Manual: $100-$500

Semi-auto: $1,000-$10,000

Fully auto: $20,000-$500,000+

Be cautious of “theoretical speeds” quoted by suppliers. These are often based on the smallest capsule sizes (e.g., Size 3 or 4).

The Reality: If you are filling large capsules like Size 00 or 000, the actual stable output will likely be 10–20% lower due to the physical limitations of the mold cavities.

Action: Ask the supplier to specify the “Stable Working Output” for your specific capsule size and material. Reputable suppliers will provide these realistic figures, for example, “150,000/hour theoretical, 125,000/hour stable for Size 00.”

Yes, absolutely. Insist on a Factory Acceptance Test.

Process: Send a batch of your empty capsule shells and a few kilograms of your powder blend to the manufacturer.

What to Verify:

Fill Accuracy: Can the machine consistently achieve your target weight within the required tolerance (usually ±2% to 5% )?

Yield/Reject Rate: What percentage of capsules are damaged or mis-filled? The industry standard is a reject rate of less than 1% .

Material Handling: Observe how your powder flows through the machine. Does it bridge or clog in the hopper?

A reliable manufacturer will:

Welcome you to visit their factory and meet the engineering team.

Provide the machine’s unique serial number and QA logs.

Have engineers available to answer detailed technical questions about mechanical design or software logic, not just salespeople.

Offer a transparent spare parts list with pricing upfront, allowing you to estimate your total cost of ownership for the next 2–3 years.

Standard operating procedure involves three key checks:

Environmental Check: Ensure the room temperature is 18–26°C (64–79°F) and humidity is 45–65% RH. Incorrect humidity makes capsules brittle (too dry) or sticky (too humid).

Material Handling: Pre-sieve your powder through an 80–100 mesh screen to break up agglomerates. Crucially, know the bulk density of your powder—this is the primary data point for calibrating the filling weight.

Machine Check: Verify compressed air pressure (0.4–0.6 MPa / 58–87 PSI), power supply, and that all safety guards and emergency stops are functional.

Powders with a high angle of repose (>40°) or that are sticky can cause inconsistent filling. Solutions include:

Formulation Adjustments: Add glidants like fumed silica or magnesium stearate to improve flow. Granulating the powder (creating larger, denser particles) is the most effective solution.

Machine Adjustments:

For very “floodable” powders that flow like water, you may need a compression screw (smaller pitch) to prevent the material from leaking out of the dosing chamber uncontrollably.

Ensure the agitator forks or paddles inside the hopper are working correctly to prevent bridging.

Inconsistent fill weight is the most common issue. Troubleshoot in this order:

Powder Condition: Check for segregation, clumps, or changes in moisture content in the hopper.

Dosing System: For dosator machines, check if powder is sticking to the tips of the filling pistons (“picking”). For tamping machines, check if the tamping pins are worn or if the holes in the dosing disc are clogged.

Mechanical Wear: Inspect the dosing disc or pistons for wear. Worn components cannot create a consistent vacuum or compression, leading to weight variation.

WhatsApp us