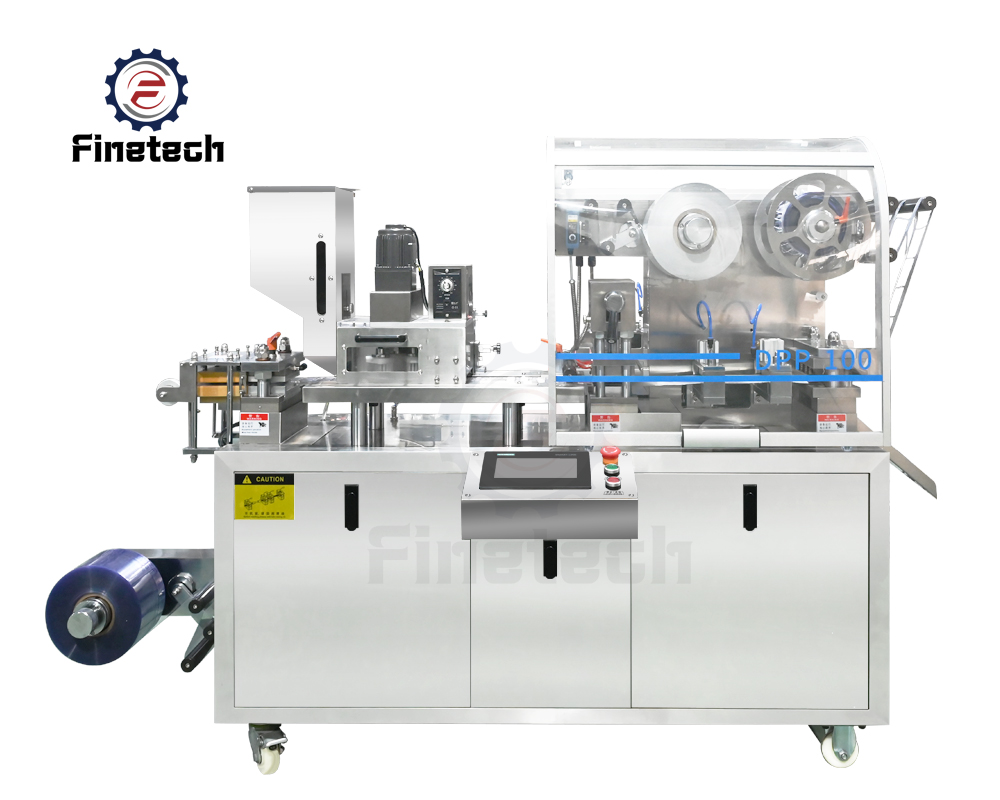

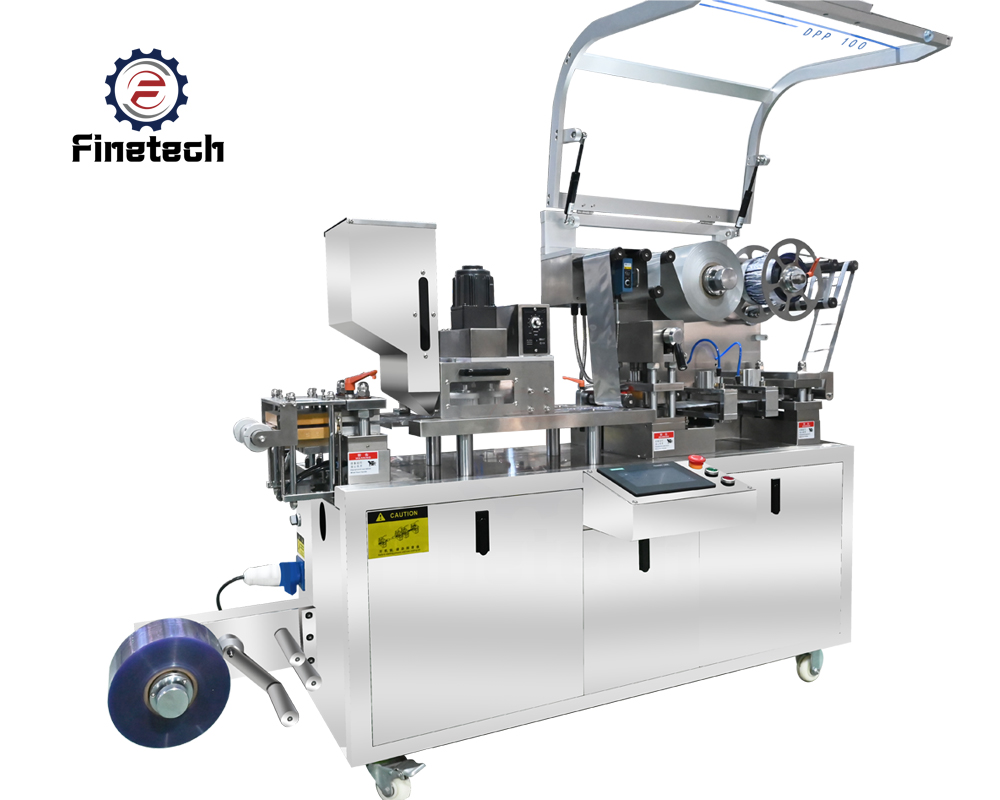

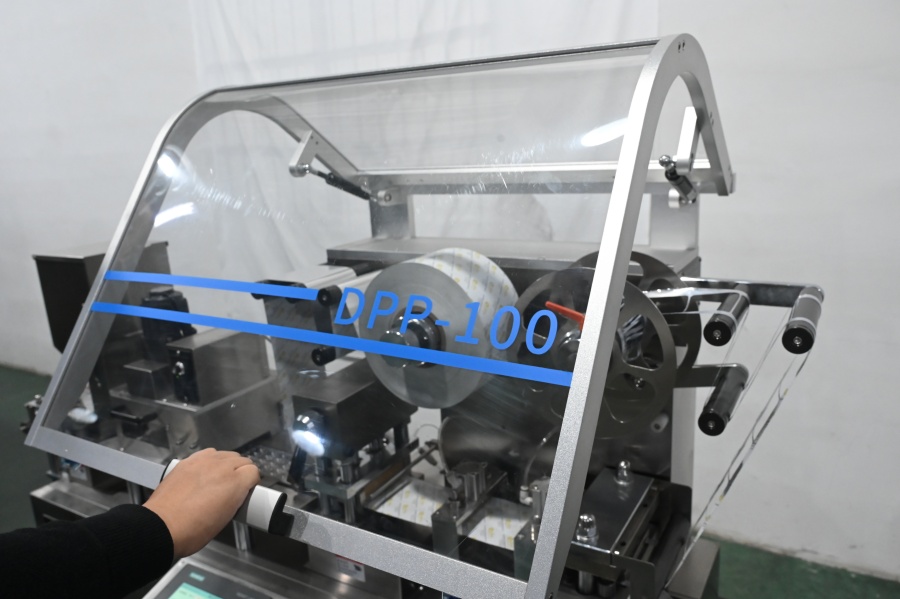

DPP-100 Blister Packing Machine

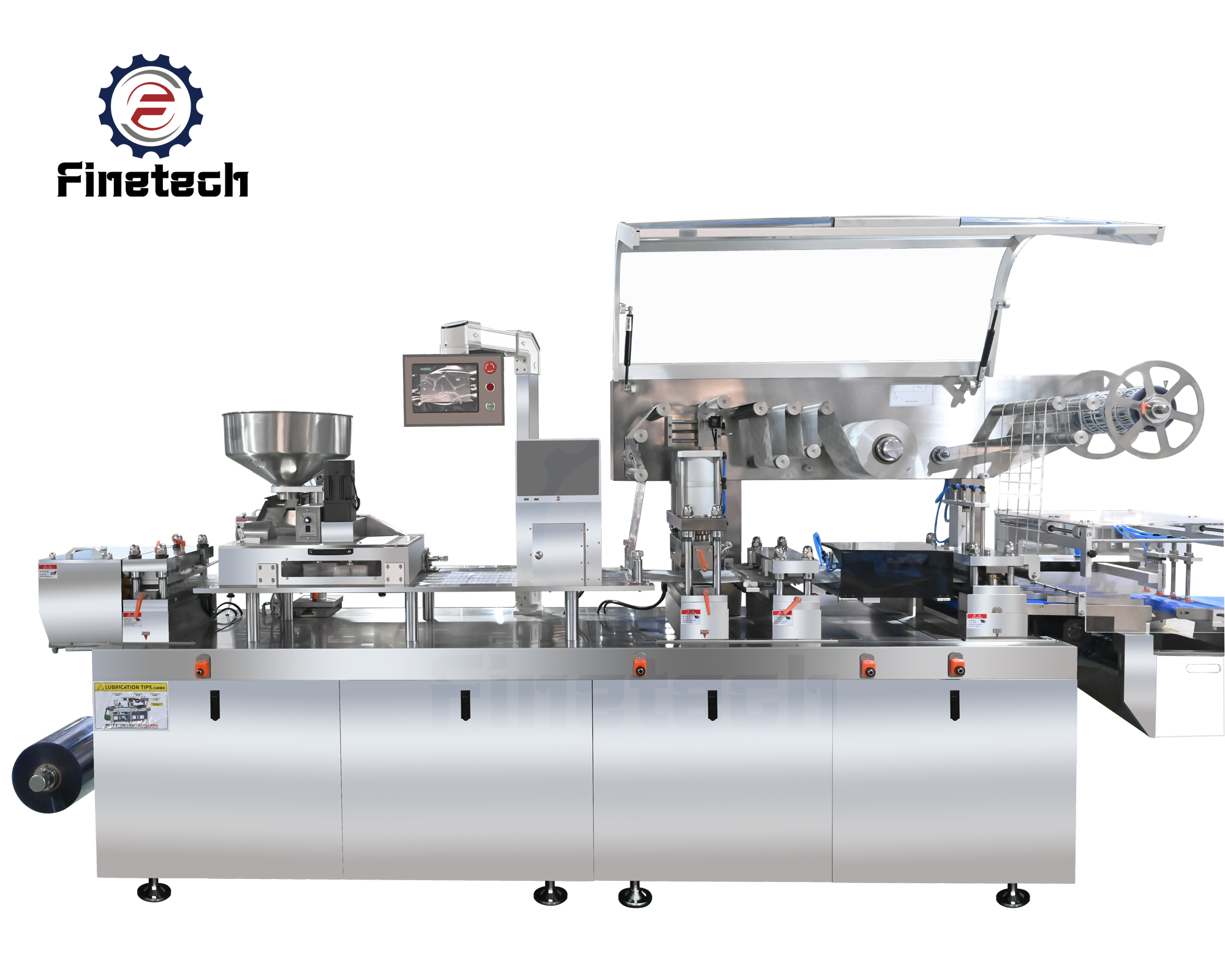

The DPP-100 is an economical automatic blister packaging machine that supports aluminum-plastic packaging using PVC or PVDC aluminum foil. It features a servo drive and PLC control and is designed mainly for small to medium pharmaceutical companies, health supplement makers, and labs. It is suitable for individually sealed packaging of tablets, capsules, gummies, and similar products.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

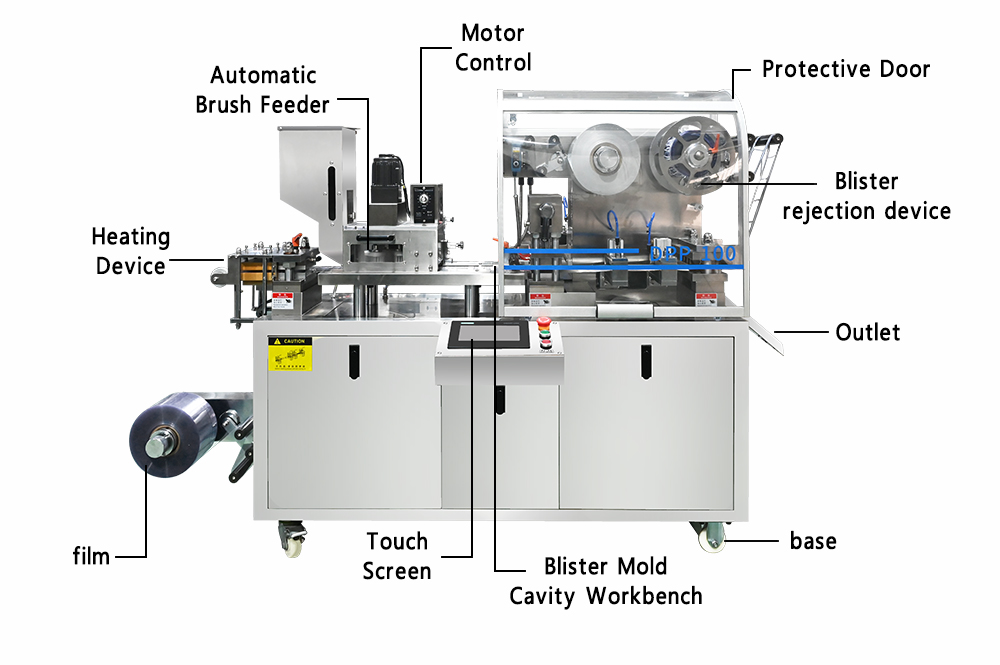

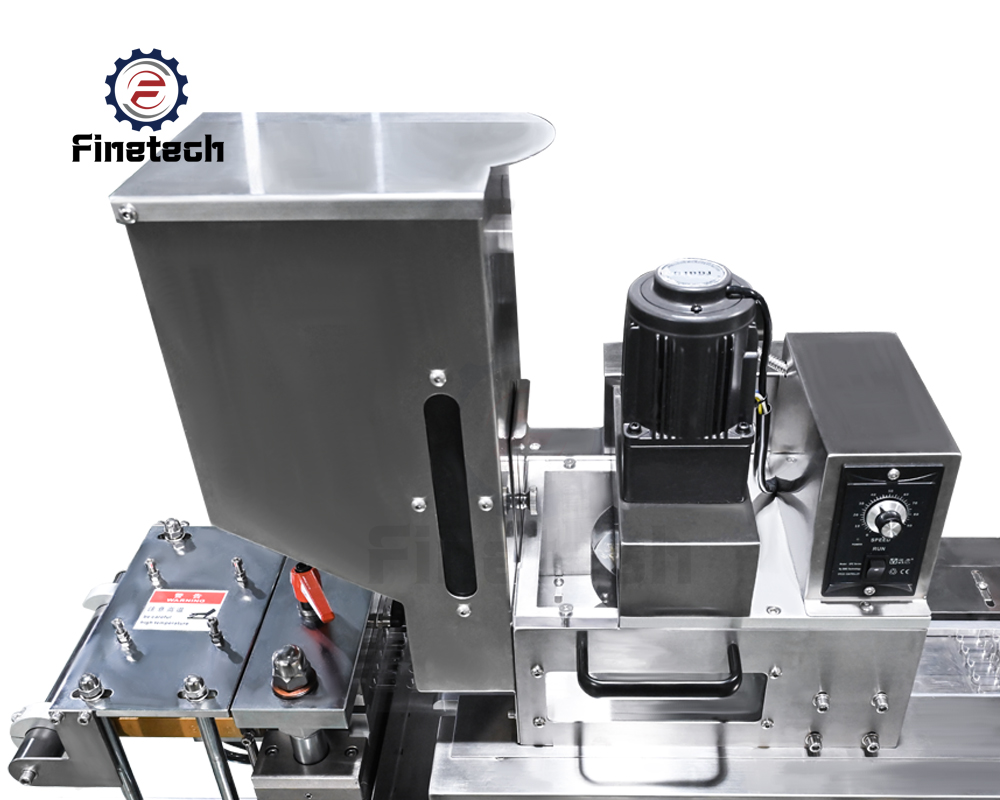

1. Simple Machine Structure: The transmission system is optimized from the original design, providing a wider forming range, more precise transmission, and lower noise.

2. Hollow Platform: The working surface is separated from the drive system below, preventing cross-contamination and making cleaning easier.

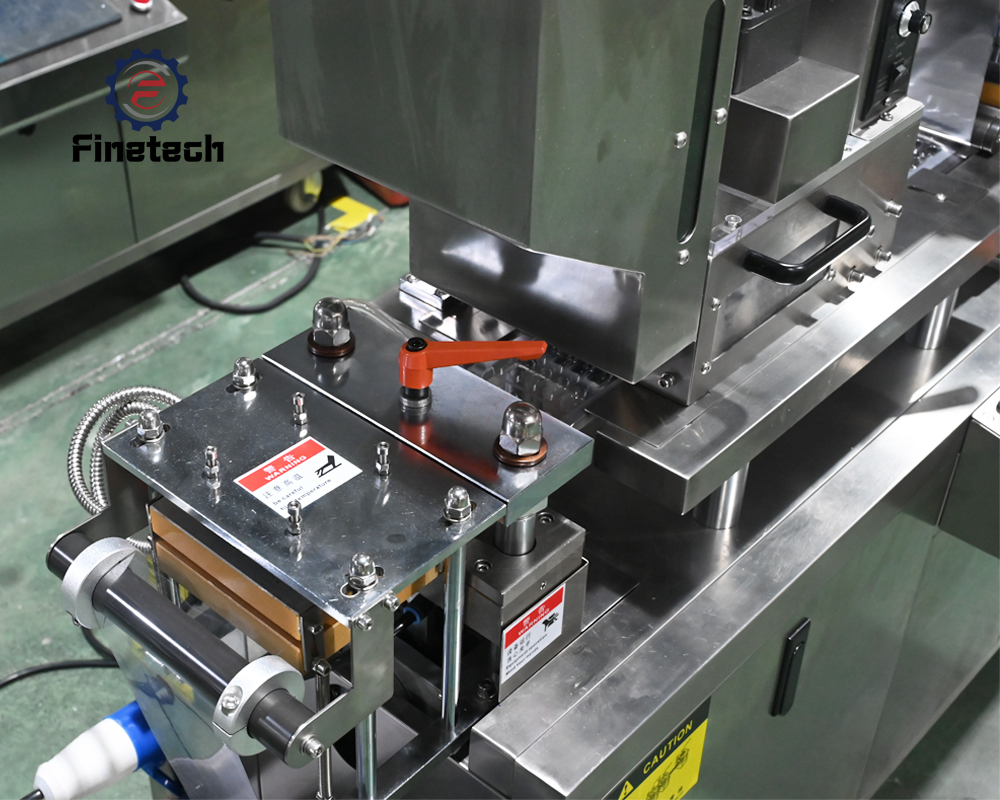

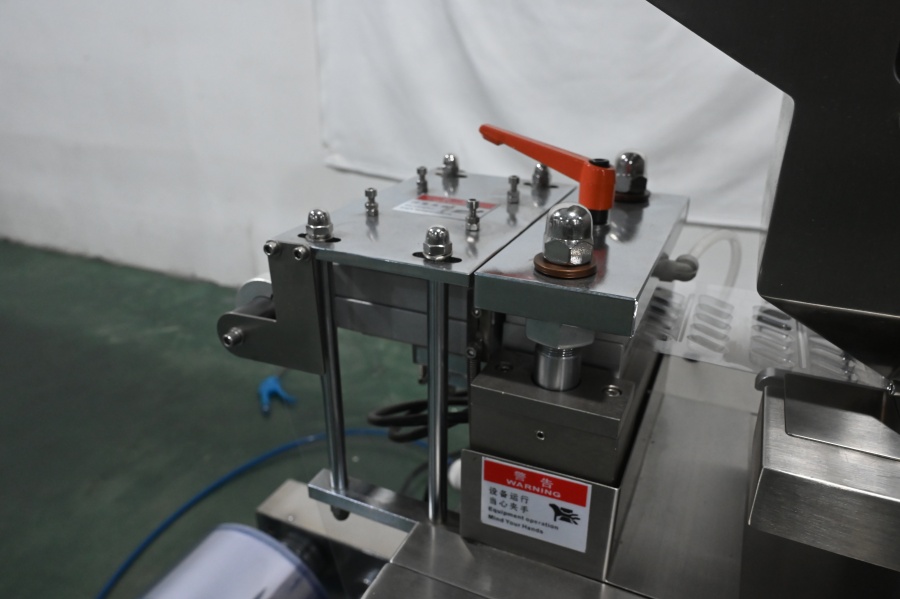

3. Quick-Release Molds: Each station has a positioning reference for fast mold changes. All adjustment parts have scale markings for precise tuning based on product needs.

4. Automatic Waste Collection: Waste is collected automatically, enabling standardized, automated production and reducing labor.

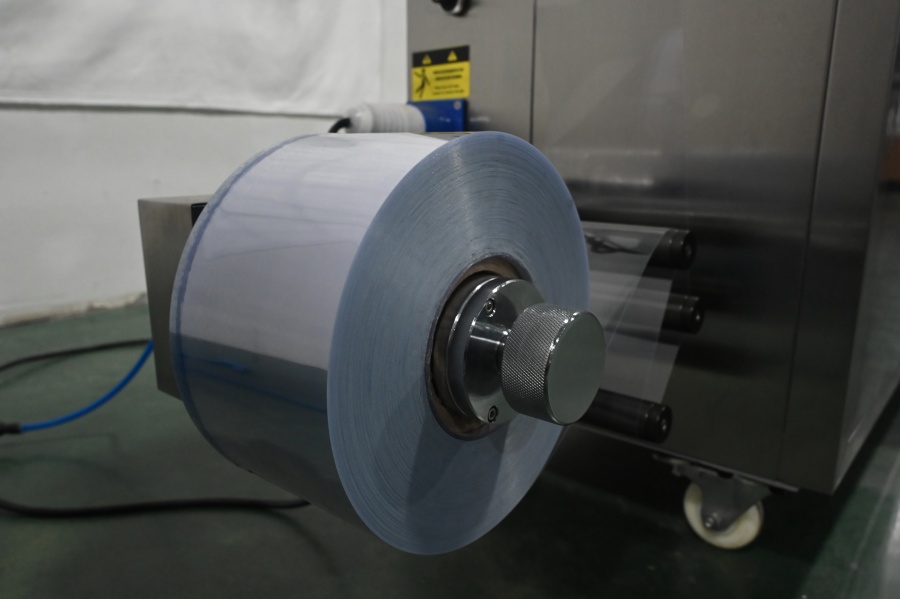

5. Manual Material Shaft: Makes loading and unloading material faster and easier.

6. Customizable Features: Includes color mark registration, indentation units, and secondary forming.

| Model | DPP-100 Blister Packing Machine |

| Production Capacity | 2320plates/h |

| Cutting Frequency | 1980 plates/h |

| Adjusting range of travel | 35-75 mm (Aluminum-Plastic) 30-75 mm (Aluminum-Aluminum) |

| Max. forming area | 75x105mm |

| Max. forming depth | 16 mm (Aluminum-Plastic) 12 mm (Aluminum-Aluminum) 24 mm (Customizable) |

| Size of standard plate | 80x57mm |

| Power supply | 220V 50Hz 3.0Kw |

| Main motor | 0.75Kw |

| Air demand | ≥0.2m³/min |

| Air pressure | 0.4-0.6Mpa |

| Dialysis paper | 50-100gx120mm |

| Cooling of mold | Tap water or cycling water |

| Width and thickness of PVC and PTP | PVC:0.15-0.5x120mm PTP:0.02-0.035x120mm |

| Overall size | 1996x592x1229mm |

| Weight | 460 kg (Net Weight) 520 kg (Gross Weight) |

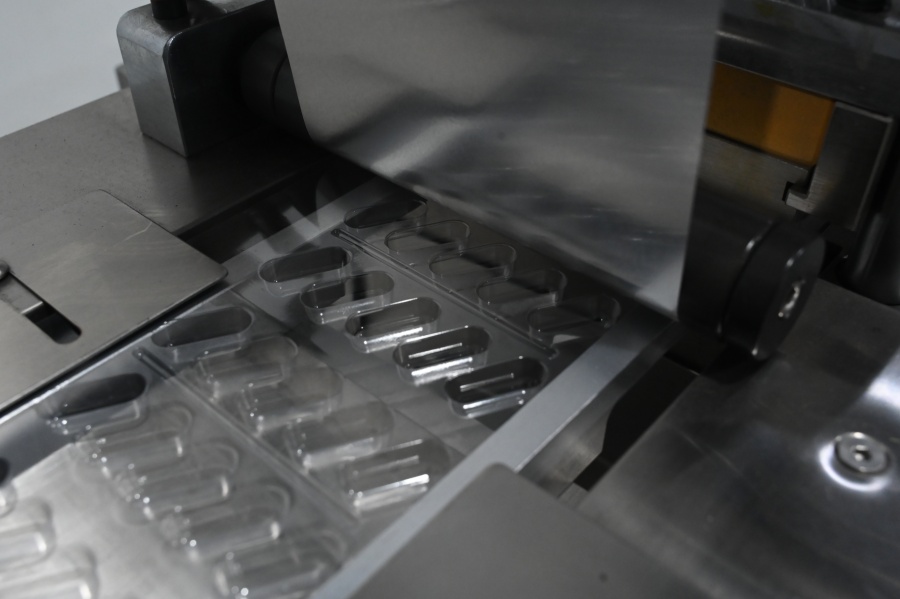

The DPP-100 is primarily used in the pharmaceutical industry for blister packaging tablets, capsules, gel caps, and lozenges. It can also be used for small items in the food, electronics, and consumer goods industries.

Speeds can vary based on product size and tooling, but a typical DPP-100 machine operates in the range of 40 to 100 cycles per minute. The exact output will depend on your specific configuration.

Forming Film: PVC, PVDC-coated PVC, Aclar-coated PVC, PP, PE, and other thermoformable plastics.

Lidding Material: Hard temper aluminum foil (e.g., 20-25µm), Paper/PET/PE laminates, and Push-through Foil (PTF).

Yes. The DPP-100 is designed with Good Manufacturing Practice (GMP) in mind. It typically features a open and accessible design with easy-to-remove parts and stainless steel contact surfaces for simplified cleaning and maintenance.

This varies, but generally, the machine requires:

Electrical Power: 380V/220V, 3-phase, 50/60 Hz.

Compressed Air: A clean, dry air supply at a pressure of approximately 0.6-0.8 MPa (6-8 bar).

Heating: Electrical heating for the forming and sealing stations.

The DPP-100 is designed for relatively quick changeover. The process involves:

Replacing the forming and sealing molds/dies.

Changing the feeding parts (vibratory bowl, tracks).

Adjusting the film indexing length and heating temperatures.

With proper training and organization, changeovers can typically be completed in 30-60 minutes.

You will need custom-made tooling for each unique product shape and blister pack design. This includes:

Forming Mold: Creates the pockets in the blister film.

Sealing Mold: Seals the lidding foil to the formed blister.

Punching Mold: Cuts the finished blister into the final strip format (e.g., 2x4, 3x3).

Product Feeding Parts: Custom vibratory bowl and conveying tracks.