Tube Filling and Sealing Machine

Finetech offers semi-automatic to fully automatic tube filling and sealing machines for the cosmetics industry, with a filling volume ranging from 3 mL to 300 mL.

Learn More About our Tube Filling and Sealing Machines

The Tube Filling and Sealing Machine is an automated or semi-automated system designed to fill and seal tubes made of plastic (laminate, PE, PET) or aluminum. These machines are widely used in industries like pharmaceuticals, cosmetics, food, and chemicals for packaging products such as creams, gels, ointments, pastes, and liquids.

Operation speed: 30-60units/min

Filling volume: 0.5 – 300ml

Filling precision: ±1%

Operation speed: 60-80 tubes/min

Filling volume: 5-250ml

Filling precision: ≤±1%

Suitable tube length: 50-210mm

Operation speed: 80 tubes/min/(max)

Filling volume: 1 – 300ml

Filling precision: ≤±0.5%

Filling speed: 150 tubes/ min

Filling volume: 2 – 200ml

Filling precision: ≤±1%

Operation speed: 18 – 28 tubes/ min

Filling volume: 6 – 60ml、10 – 120ml、25 – 250ml

Filling precision: ±1%

Operation speed: 50-60 tubes/min

Filling Effervescent tablet numbers: 8-30 pcs

Filling precision: ≤±1%

Suitable tube diameter: 23mm-29mm

Specification

| Model | FT-09 | FT-60A | FT-80A | FT-120A | FT-30 | FT-80 | FT-150 |

|---|---|---|---|---|---|---|---|

| Operation speed | 18 - 28 units/ min | 60units/min(max) | 80units/min(max) | 120units/min(max) | 30-60units/min | 80units/min(max) | 150units/ min |

| Filling volume | 6 - 60ml、10 - 120ml、25 - 250ml | 5-250ml | 5-250ml | 5-250ml | 0.5 - 300ml | 1 - 300ml | 2 - 200ml |

| Filling precision | ±1% | ≤±1% | ≤±1% | ≤±1% | ≤±1% | ≤±0.5% | ≤±1% |

| Suitable tube length | 70 - 210mm | 50-210mm | 50-210mm | 50 - 150mm | 50 - 200mm | 210mm(customizable) | 50 - 200mm |

| Suitable tube diameter | ⌀16 - 50mm | ⌀13-50mm | ⌀13-50mm | ⌀12 - 35mm | ⌀10 - 50mm | ⌀10 - 50mm | ⌀10 - 35mm |

Applications

Learn more about our Tube Filling and Sealing Machines

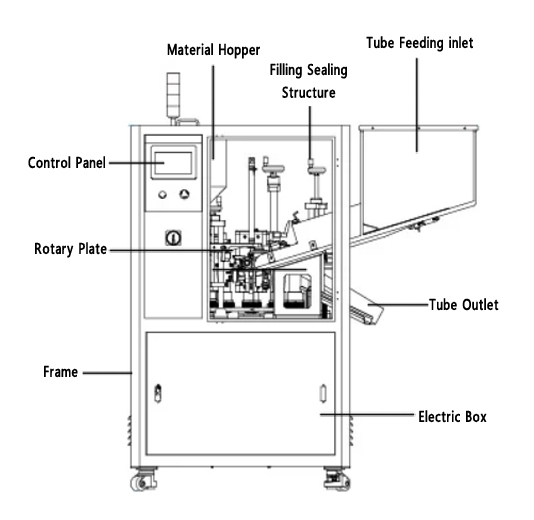

Key Components of the Tube Filler and Sealer

Ensures drip-free filling with adjustable height.

Nozzle Assembly

Controls machine operations.

PLC (Programmable Logic Controller)

Checks the tube volume and removes the waste tubes.

Photoelectric Sensor

Volume options: 20 L, 50 L, 70 L, 100 L, 150 L, 200L.

Material TankHow Does Tube Filling and Sealing Machine Work

- Step 1. Feeding:Empty tubes are loaded either automatically via conveyor or manually, with proper orientation (open end up).

- Step 2. Positioning: Clamps secure tubes while vision systems ensure precise alignment for filling.

- Step 3. Filling: Product is dosed using piston (for pastes), peristaltic pump (liquids) or auger (powders) with ±0.5% accuracy.

- Step 4. Cleaning (Optional): Wipers or vacuum nozzles remove excess material from tube openings.

- Step 5. Sealing: Tubes are sealed via heat (plastics), crimping (metal) or ultrasonic (heat-sensitive products).

- Step 6. Capping: Automatic systems apply screw-on or snap-on caps to finished tubes.

- Step 7.Marking (Optional): Date codes/batch numbers are printed via inkjet, laser or hot stamp methods.

- Step 8. Discharge: Finished tubes exit via conveyor for secondary packaging or palletizing.

FAQ

Plastic tubes (laminate, PE, PET)

Aluminum tubes

Laminated tubes (for sensitive products)

Piston filling – Best for thick products (creams, ointments)

Peristaltic pump – For liquids, sterile solutions

Auger filling – For powders or semi-solids

Manual/Semi-automatic: 10-30 tubes/minute

Automatic: 30-80 tubes/minute

High-speed rotary: 80-200+ tubes/minute

The regular filling capacity is 5 mL to 250 mL. If you need to exceed 250 mL, you can choose our customized services.

Pharma (ointments, gels, nasal sprays)

Cosmetics (lotions, toothpaste)

Food (condiments, sauces)

Industrial (adhesives, lubricants)

Semi-automatic: Manual loading, lower speed, lower cost

Fully automatic: Auto-loading, higher speed, PLC-controlled

Yes, integrated printers (inkjet/laser) can mark:

Batch numbers

Expiration dates

Barcodes

Automatically orients and feeds empty tubes.

Tube Hopper/Vibrating Feeder