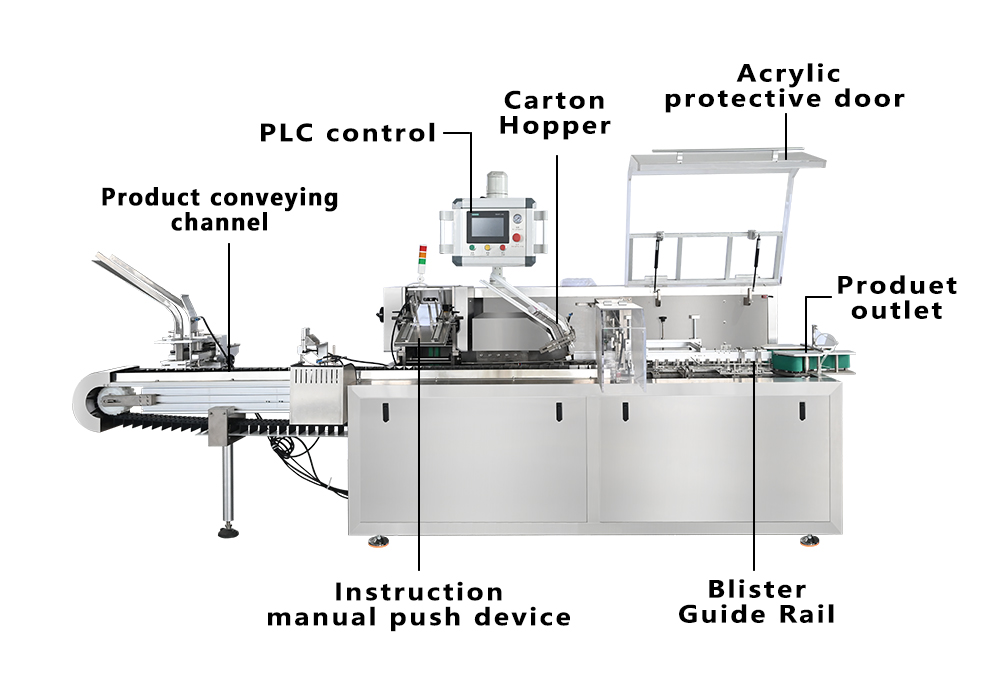

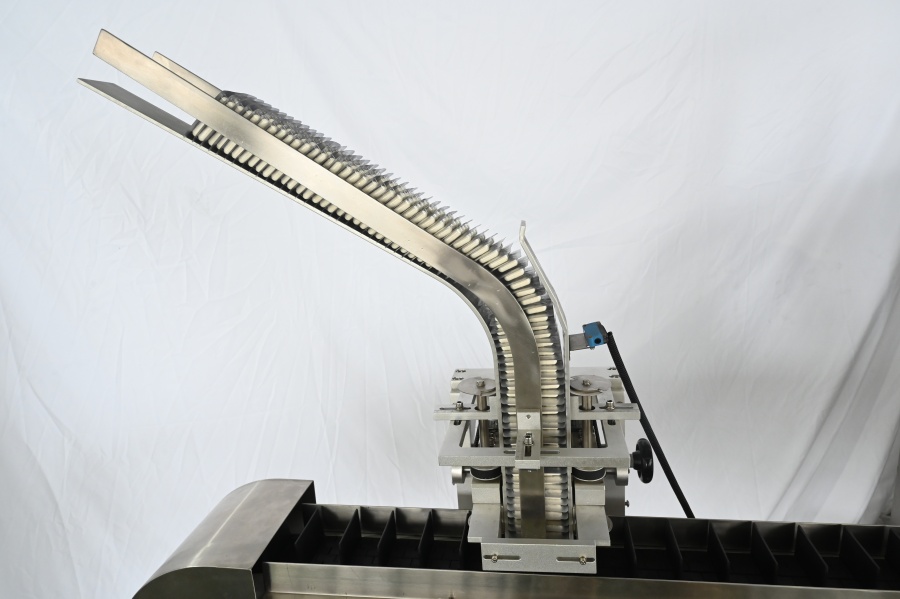

FTZH-130 Automatic Horizontal Cartoning Machine

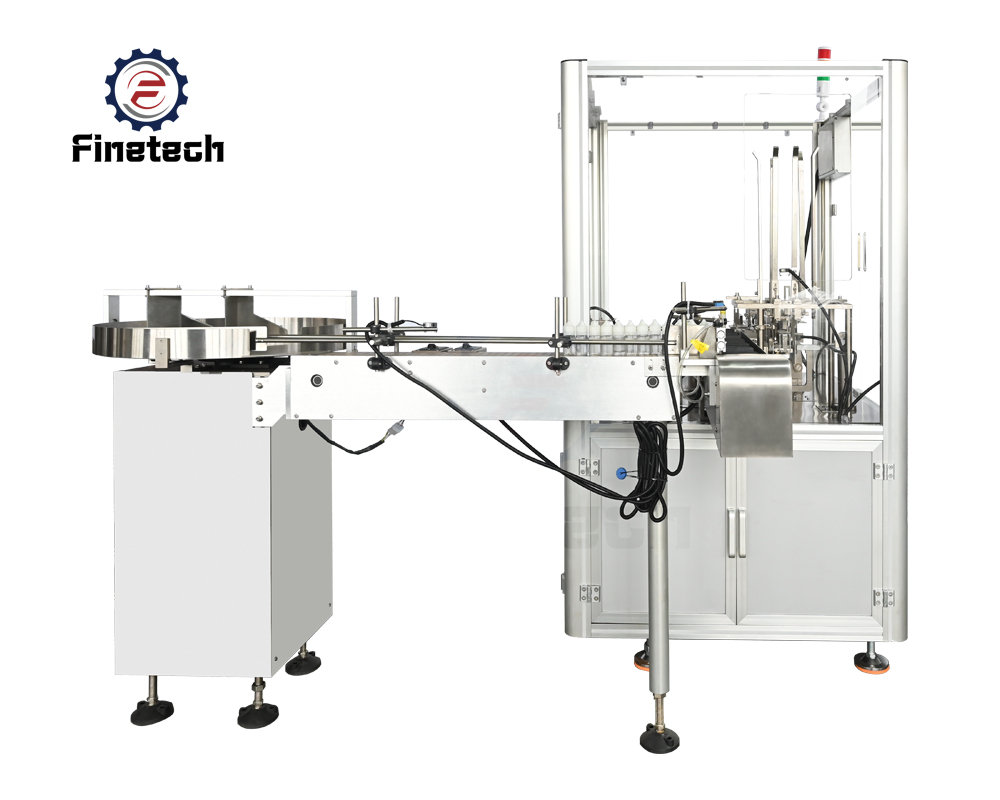

The FTZH-130 fully automatic Horizontal cartoning machine is an upgraded version, redesigned using the newest technology to greatly improve performance. It can pack up to 120 cartons per minute while remaining stable at high speeds. This machine is ideal for packing medicines (blister packs) or plastic and glass bottles into cartons. It automates the entire process, including inserting instruction leaflets and sealing carton flaps, with optional hot melt glue sealing.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

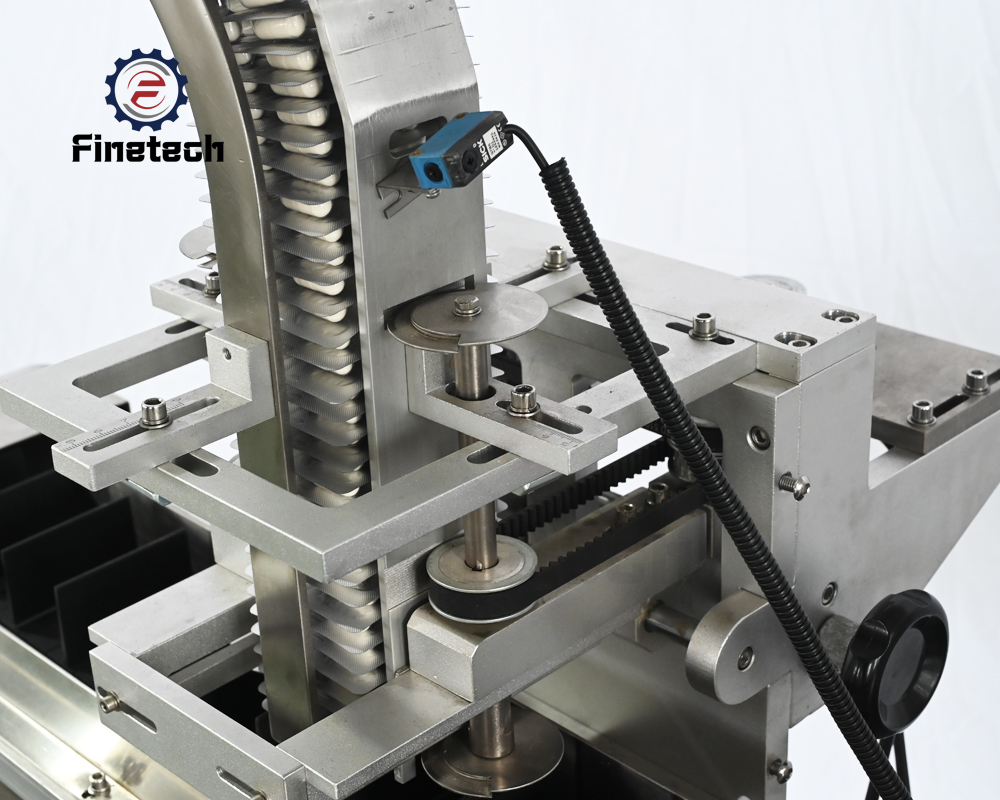

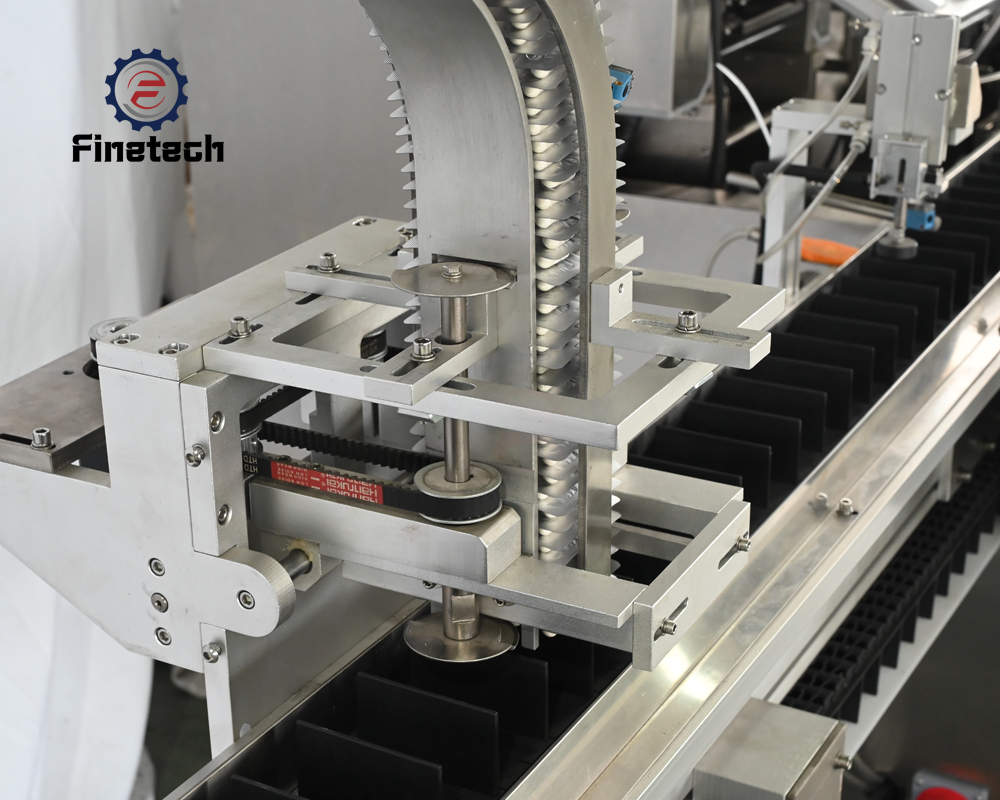

1.The main frame has a vertical partition separating the drive section at the back and front. It’s suitable for packing blister packs, bottles, vials, pillow packs, and more.

2.The machine runs very well and easy pack different carton sizes.

3.It can fold instruction leaflets, open cartons, place products and leaflets inside, emboss, seal the flaps by inserting or hot melt glue, and automatically discharge the cartons.

4. The machine has sensors and safety devices to ensure operater safety and high speed cartoning.

5. It can connect with blister packers, pillow pack machines, outer packaging machines, and other equipment to form a complete packaging line.

| Model | FTZH-130 Automatic Horizontal Cartoning Machine |

| Packing speed | 30 – 130Cartons/min |

| Carton size range | (65 – 155)mm×(30 – 85)mm×(15 – 50)mm |

| Carton gram requirements | 250 – 350g/m² |

| Motor power | 0.75kw |

| Power supply | 220V 50Hz |

| Machine noise | < 75db |

| Air pressure | ≥0.6Mpa |

| Air consumption | 120 – 160L/min |

| Dimension | 2300mm×1140mm×1800mm |

| Weight | 1200kg |

Its primary function is to automatically erect cartons from flat blanks, insert one or multiple products into them, and then close the flaps. The "horizontal" refers to the orientation of the carton as it is being processed and filled.

Speeds vary greatly by model and product complexity. A standard machine might run between 80 to 250 cartons per minute. High-speed models can exceed 400 CPM, while slower, more complex machines might run below 80 CPM.

Virtually any item that fits into a box. Common examples include:

Pharmaceutical: Blister packs, vials, bottles, syringes.

Cosmetics: Cream jars, lipstick tubes, perfume boxes.

Food: Tea bags, snack bars, pouches.

Consumer Goods: Batteries, small electronics, lighters.

Electrical Power: Typically 3-Phase, 400V/480V or 200V/240V, depending on the region.

Compressed Air: Clean, dry air is critical for pneumatics and actuators. Typical pressure: 6-8 bar (80-115 psi).

Vacuum: For pick-and-place arms and carton erection.

Glue System (if applicable): Hot melt adhesive unit and compressed air for the glue gun.

Changeover time depends on the machine's design. It can range from:

Quick Changeover (15-30 minutes): For machines with tool-less adjustments and quick-release mechanisms.

Standard Changeover (30-90 minutes): Requiring the swap-out of product flights, pushers, and adjustment of guides and hoppers.

Common change parts include:

Carton Magazine and Carton Grippers to handle the new blank size.

Product Flight Bars and Pushers/Fingers that match the new product's dimensions.

Infeed Guides and Tracks for the product.

Closing Folding Rails to accommodate the new carton size.

Vacuum Failure: Vacuum cups are worn, cracked, or blocked. Vacuum pump pressure is low.

Gripper Issues: Mechanical grippers are misadjusted or worn.

Blank Warping or Static: Poor quality blanks or static electricity causing them to stick together.

Magazine Settings: Incorrect pressure on the blank stack.