Plastic Ampoule Filling and Sealing Machine

The plastic ampoule filling and sealing machine is an automated system designed to fill liquids or oils (such as pharmaceuticals, vaccines, cosmetics, or essential oils) and hermetically seal them for sterile, leak-proof packaging.

Learn More About Our Plastic Ampoule Filling and Sealing Equipment

Volumes can range from 0.5 mL to 20 mL for filling, sealing, and other aseptic liquid.

Application: Pet medicine, mouthwash, cosmetic samples, perfume samples, oral solutions, cooking oils, enemas, injections, and more.

Max forming depth: 12mm

Machine weight: 900kg

Overall dimension (L*W*H): 2300x850x1400(mm)

Max forming depth: 12mm

Machine weight: 1200kg

Overall dimension (L*W*H): 5200x1050x1800(mm)

Specification

| Model | GGS-118(P2) | GGS-118(P5) | GGS-240(P5) | GGS-240(P10) | GGS-240(15) |

|---|---|---|---|---|---|

| Max forming depth | 12mm | 12mm | 12mm | 12mm | 12mm |

| Punch frequency | 0-25time | 0-25time | 0-25time | 180-250time/pre | 25time 22000units/h |

| Packing material | PVC/PE,PET/PE(0.2-0.4)x140mm | PVC/PE,PET/PE(0.2-0.4)x140mm | PVC/PE,PET/PE(0.2-0.4)140xmm | PET/PE,PVC/PE,PVE/EVOH | PET/PE, PVC/PE,PVE/EVOH |

| Filling volume | 1-50ml | 1-50ml | 1-50ml | 1-100ml | 1-100ml |

| Toal power supply power | 4.3KW | 7KW | 7KW | 22KW | 22KW |

| Voltage | 220-380V/50Hz | 220-380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Machine weight | 700Kg | 900Kg | 1200Kg | 2000Kg | 3000Kg |

| Overall dimension (L*W*H) | 1750x750x1400(mm) | 2300x850x1400(mm) | 3200x850x1400(mm) | 5200x1050x1800(mm) | 7300x1050x1800(mm) |

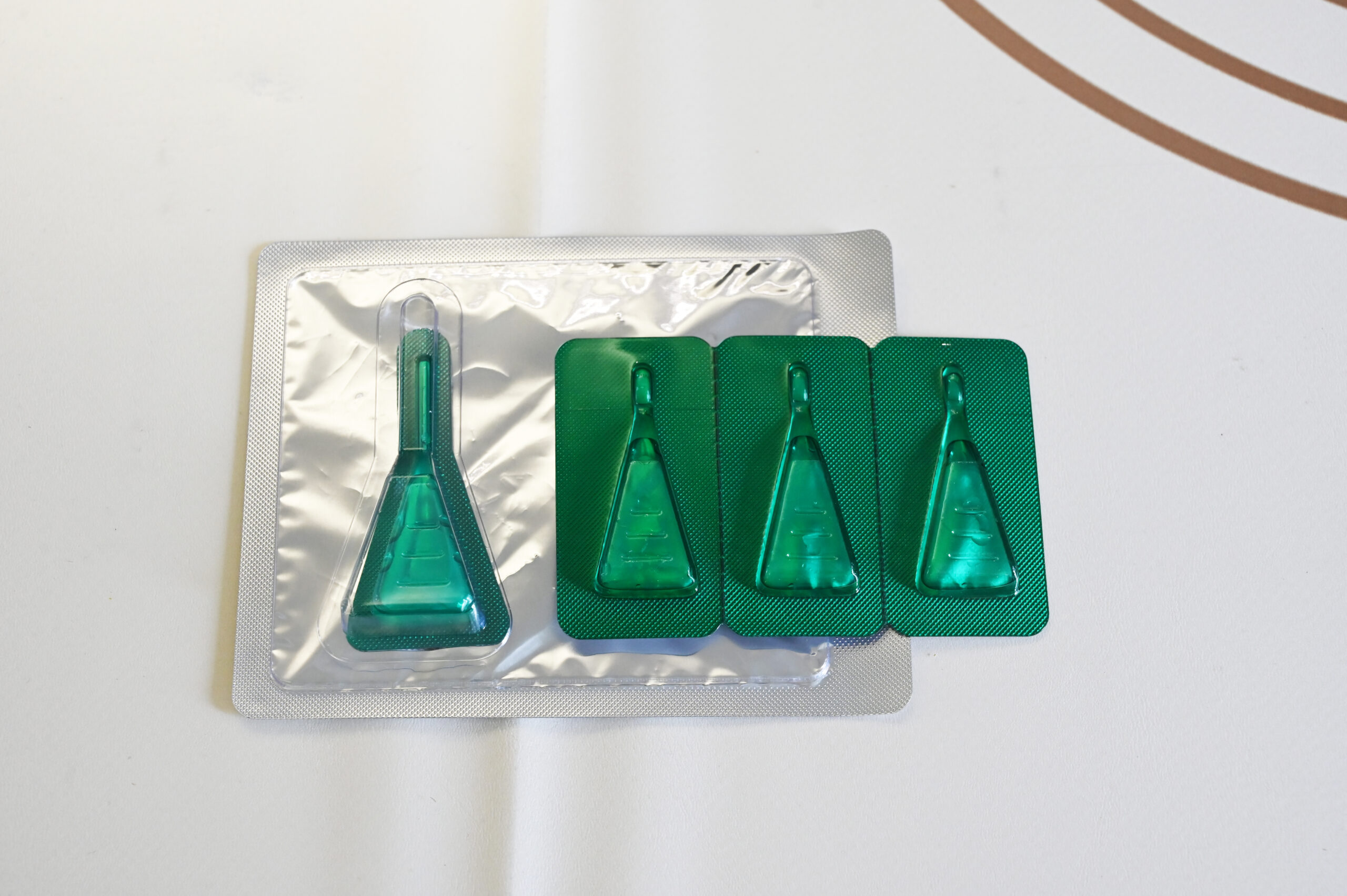

Applicable Products

Learn more about our plastic ampoule machines

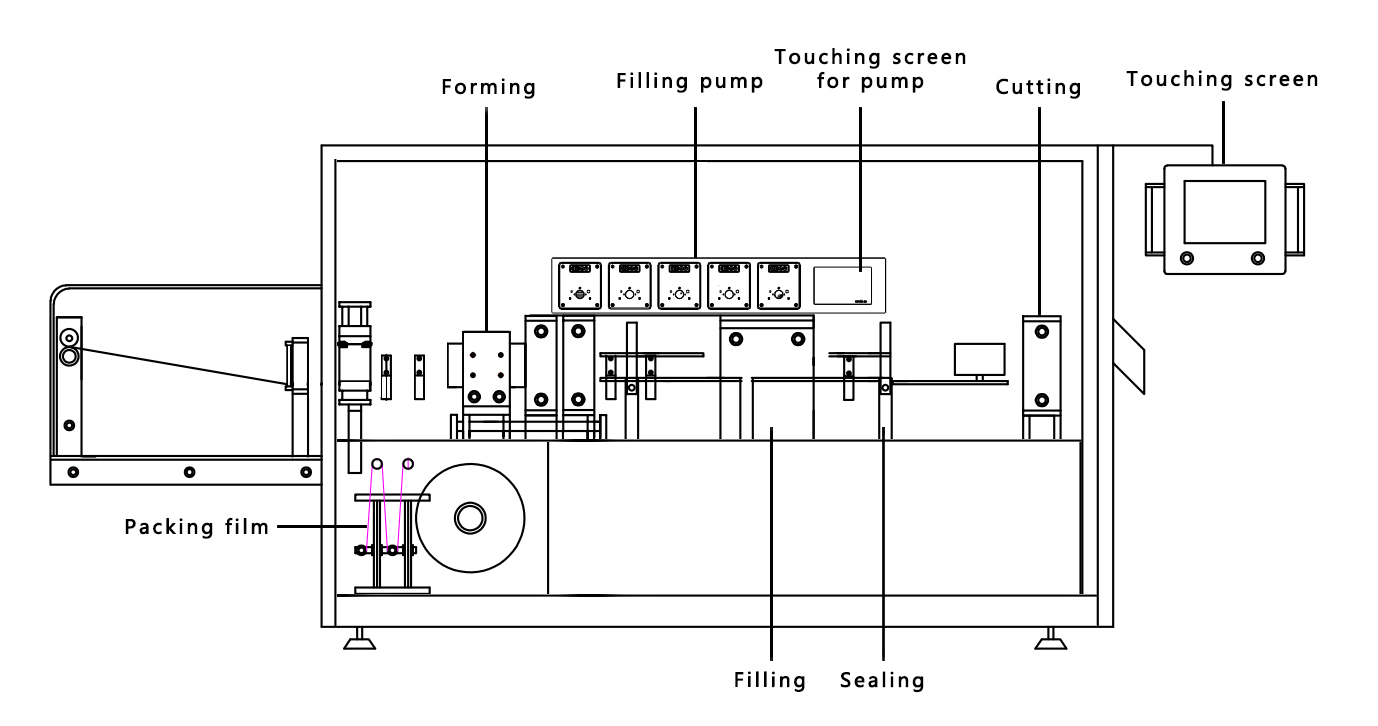

Key Components of the Plastic Ampoule Filling and Sealing Machine

Uses controlled heat to melt and seal the ampoule neck.

Sealing System

The HMI (Human-Machine Interface) allows operator input and monitoring.

Control & Automation SystemPlastic Ampoule Filling and Sealing Machine Working Principle

- Step 1. Ampoule Feeding: Plastic ampoules are automatically fed into the machine and positioned for filling via conveyor.

- Step 2.Filling Process: Precision pumps accurately dose liquid into ampoules without contamination.

- Step 3.Sealing Process: Heat or ultrasonic energy melts the neck, which is pressed to form an airtight seal.

- Step 4. Cooling & Discharge:Sealed ampoules are cooled and automatically discharged as finished products.

FAQ

Common materials include:

Polypropylene (PP) – Heat-resistant, autoclavable.

Polyethylene (PE) – Flexible, chemical-resistant.

Cyclic Olefin Copolymer (COC) – High clarity, low moisture absorption.

Pharmaceuticals (injectables, vaccines, eye drops, oral solutions).

Cosmetics (serums, essential oils).

Food & Beverage (single-use liquid samples).

Laboratories (reagents, diagnostic fluids).

Typically ±1% to ±0.5% depending on the pump type (peristaltic, piston, or servo-driven).

Yes, most machines have adjustable settings for different volumes (e.g., 1 mL to 30 mL).

The speed ranges from 30 to 300 ampoules per minute, depending on machine type (semi-automatic or fully automatic).

Yes, our machines meet all of the following requirements:

GMP (Good Manufacturing Practice)

FDA 21 CFR Part 210/211 (for pharmaceuticals)

CE & ISO Standards

Yes, with piston fillers or positive displacement pumps for thicker solutions such as gels and suspensions.

316 filling heads for aseptic filling

Filling System