Tablet & Capsule Polishing Machine

Capsule polishers are responsible for overlaying a shiny coating on capsules and tablets, making them easier to swallow.

View Our Complete Line of Capsule Polishers

Our capsule polishing machines are made of 316L stainless steel, with polished surfaces that can safely come in contact with capsules and tablets.

The YJP-A capsule polishing machine can effectively remove dust from the capsule’s surface and increase its glossiness. It is suitable for capsules of various sizes. The surface of the machine is polished and each part can be quickly disassembled and cleaned.

FTP-110A is a newly designed Capsule Polisher to polish capsules and tablets, it is a must for any company producing hard gelatin capsules.

The LFP-150A series capsule polishing machine integrates polishing and sorting functions. It quickly removes excess dust on the capsule surface and automatically separates empty and unqualified capsules. It can be quickly installed and disassembled and is easy to move. It is auxiliary equipment for capsule filling machines.

Specification

| Model | YJP-A | JFP-110A |

|---|---|---|

| Production | 150000 Pcs/hr | 150000 Pcs/hr |

| Power | 220V,50Hz,2A, single phase | 220V,50Hz,2A, single phase |

| G.W. | 60kg | 60kg |

| N.W. | 40Kg | 40Kg |

| Negative pressure | 2.7m3/mn ---0.01mpa | 2.7m3/mn ---0.01mpa |

| Compressed air | 0.25m3/min--- 0.3mpa | 0.25m3/min--- 0.3mpa |

| Size(long*wide*high) | 1025x550x900(mm) | 800*500*1000mm |

| Package size(long*wide*high) | 1130x620x750(mm) | 870*600*720 |

Applicable Capsules

Discover the details of our Capsule Polishers

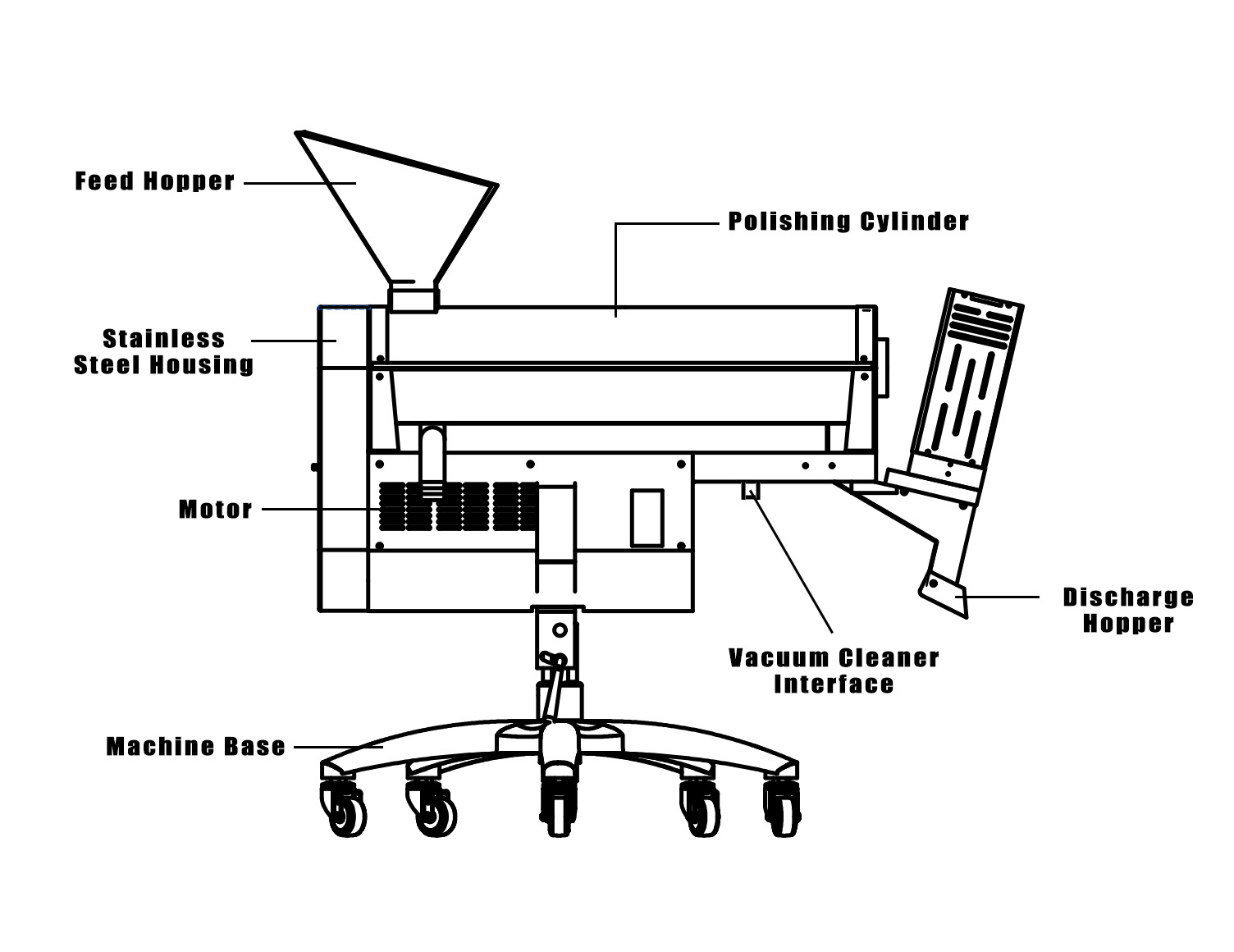

Key Components of Tablet & Capsule Polisher

Its push-button design allows easy adjustments of power levels.

Control Panel

Our average daily production capacity can reach 10 units to meet your bulk ordering needs.

Adequate inventoryHow Does Capsule Polisher Work

- Step 1, Loading: Filled capsules are poured into the machine

- Step 2, Polishing: Capsules tumble while being gently brushed

- Step 3, Cleaning: Airflow removes loose powder

- Step 4, Discharge: Finished capsules come out smooth and shiny

FAQ

A capsule polishing machine removes excess powder, improves shine, and ensures smooth surfaces on filled capsules. It is commonly used in the pharmaceutical and nutraceutical industries to enhance product appearance and quality.

It’s a specialized device that removes excess powder, dust, and static from capsules after filling, ensuring a clean, professional appearance before packaging.

Typically 5-15 minutes per batch, depending on:

Capsule size & quantity.

Level of powder residue.

Desired shine level.

No—modern machines use gentle brushing and controlled airflow to avoid cracks or deformities.

Our machines can polish capsules from sizes 00 to #4.

Yep, here is:

Gelatin capsules (most common)

Vegetarian (HPMC) capsules

Size range: Typically from #000 to #5

(Always check machine specifications for compatibility)

Varies from lab-scale (few thousand capsules/hour) to production models (100,000+ capsules/hour).

Common causes:

Speed too high: Reduce drum rotation speed

Wrong brush type: Use softer brushes for fragile capsules

Overfilling: Reduce batch size

Worn brushes: Replace if bristles are stiff/broken

Generally no. Tablets typically require different equipment (dedicated tablet dedusters/destoners) as they have different fragility and cleaning requirements.

Automatically separates empty and unqualified capsules to ensure that every capsule is up to standard.

Capsule Sorter