What is Wet Granulation Machine: A Complete Guide

A wet granulation machine is a special piece of equipment. It helps make small particles stick together. These particles become

A Rapid Mixer Granulator (RMG), also known as a High-Shear Mixer Granulator, is key pharmaceutical equipment used for wet granulation—a process that converts fine powders into dense, free-flowing granules.

Our granulators integrate mixing, wet-massing, and granulation into a single unit, improving efficiency and consistency in tablet and capsule production.

This equipment is specifically designed for the pharmaceutical, food, and chemical industries. It utilizes high-speed mixing and rotary cutting technology to achieve rapid material blending, wet granulation, and integrated drying. The three-dimensional mixing paddles ensure uniform dispersion without dead zones. Adjustable rotation speeds and cutting blades work together to produce uniform particle size distribution and high yield. The machines are operated via PLC with a touchscreen interface, and parameters can be programmed to meet GMP requirements. The fluid, dynamic design is optimized to reduce energy consumption, while corrosion-resistant stainless-steel construction ensures durability. Ideal for producing tablets, granules, and powders, this system helps improve both efficiency and product quality.

Designed for the pharmaceutical, food, and chemical industries and research institutions, this equipment integrates high-efficiency mixing and precise granulation. It features a modular, interchangeable bowl design compatible with a variety of sizes (e.g., 5 L-10 L) and supports diverse process requirements. Key advantages include fast switching, precise temperature control, uniform mixing, and low energy consumption. Fully GMP-compliant, it is suitable for wet granulation tests and small-batch production of tablets, granules, and herbal extracts. The intelligent and user-friendly operation makes it suitable for both laboratory and pilot-scale applications, facilitating efficient collaboration between R&D and flexible production.

The high shear mixer granulator is ideal for products requiring granulation in a wide range of industries, including pharmaceuticals, food additives, rubber and plastic additives, pesticides, dyes, pigments, catalysts, and daily chemicals.

| Model | FTLSG-5 | FTLSG-10 | FTSG-30 | FTSG-50 | FTSG-100 | FTSG-200 | FTSG-300 | FTSG-400 | FTSG-500 | FTSG-1000 |

|---|---|---|---|---|---|---|---|---|---|---|

| Hopper volume | 1L/3L/5L | 3L/6L/10L | 30L | 50L | 100L | 200L | 300L | 400L | 500L | 1000L |

| Feeding volume | 0.3L-4L | 0.8L-8L | 8-24L | 12-40L | 25-80L | 50-160L | 80-240L | 100-320L | 150-480L | 250-750L |

| Stirring motor | 1.5KW | 2.2KW | 3kw | 5.5KW | 7.5KW | 15KW | 18.5KW | 22KW | 30KW | 45KW |

| Stirring speed | 5-500rpm | 50-500rpm | 50-500rpm | 5-300rpm | 30-300rpm | 30-25rpm | 30-220rpm | 30-220rpm | 20-200rpm | 20-200rpm |

| Granulating motor | 0.55KW | 0.75KW | 1.1KW | 1.5KW | 3KW | 4KW | 7.5KW | 11KW | 11KW | 18.5KW |

| Granulating knife speed | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm | 50-3000rpm |

| Compressed air | 0.3 cubic meter 0.8Mpa | 0.3 cubic meter 0.8Mpa | 0.5cubic meter 0.8Mpa | 0.5cubic meter 0.8Mpa | 0.5cubic meter 0.8Mpa | 0.6cubic meter 0.8Mpa | 0.6cubic meter 0.8Mpa | 0.7cubic meter 0.8Mpa | 0.8cubic meter 0.8Mpa | 1.2cubic meter 0.8Mpa |

| Host size | 900*850*1160mm | 900*850*1160mm | 1700*600*1600mm | 1750*600*1620mm | 1760*650*1680mm | 2200*820*1950mm | 2400*1050*2150mm | 2500*1050*2300mm | 2980*1200*2500mm | 3400*1500*3500mm |

| Weight | 300kg | 300kg | 400kg | 500kg | 800kg | 1200kg | 1600kg | 1800kg | 2600kg | 3600kg |

Generates shear force for granule formation.

Impeller

Controls impeller and chopper speeds, mixing time, and spray rate.

Control Panel (HMI/PLC-Based)

Breaks apart lumps and enhances granule uniformity.

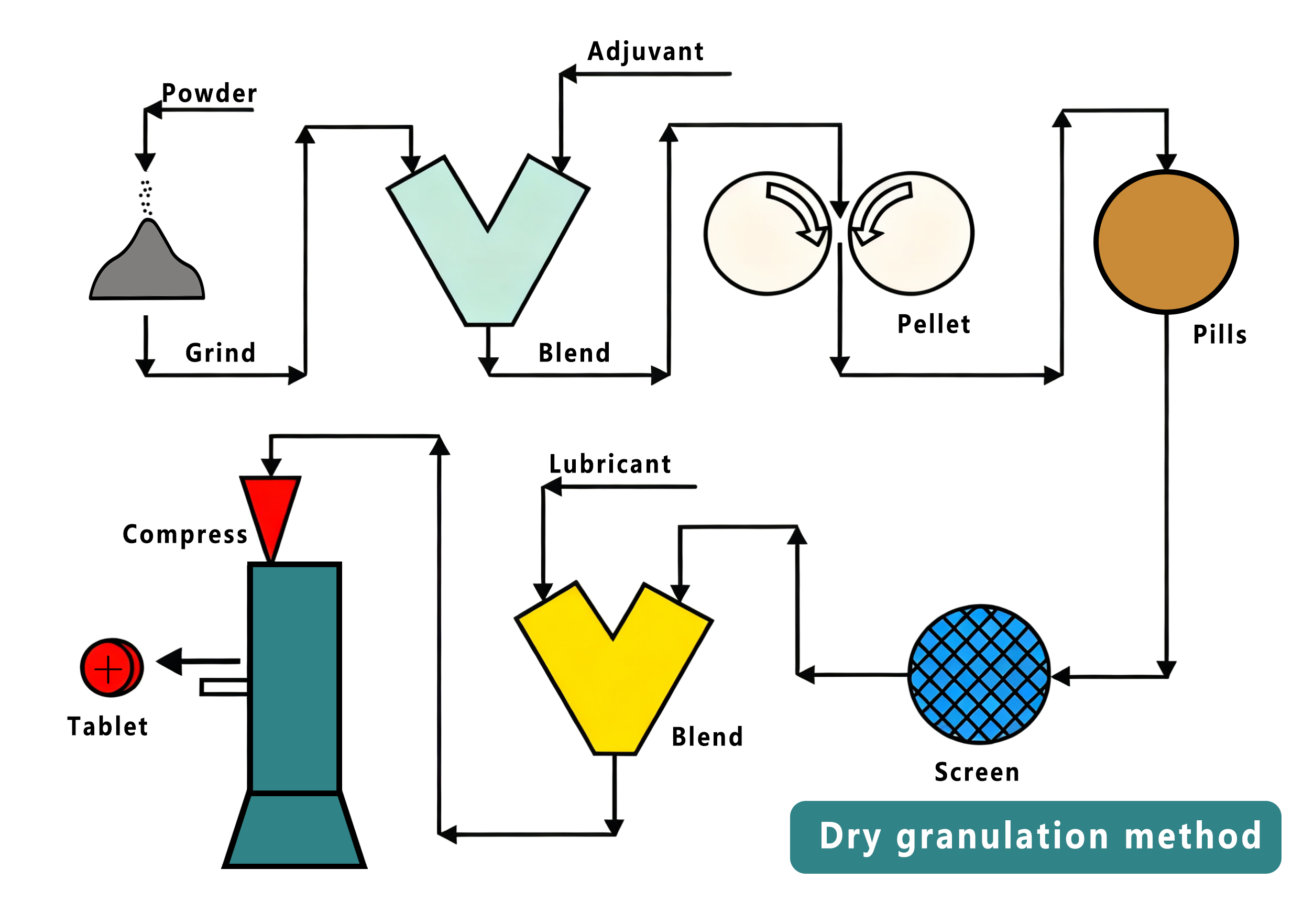

High-Speed Cutting BladeTo help you better understand the function of a granulation method……

A wet granulation machine is a special piece of equipment. It helps make small particles stick together. These particles become

Making medicine tablets might seem simple, but it takes careful work to make sure each tablet has the right amount

Making medicines is a key part of healthcare. It takes many careful steps to turn simple materials into the drugs

1.0 OBJECTIVE: 1.1 This document explains how to operate the Rapid Mixer Granulator safely and correctly. 1.2 We want consistent

An RMG is a single-pot, multi-functional machine used primarily in solid dosage (tablet/capsule) manufacturing. It performs three key operations in one vessel: dry mixing of powders, wet granulation by adding a binder liquid, and wet massing to form agglomerates.

To convert fine, poor-flowing, non-compressible powder blends into free-flowing, compressible granules suitable for tablet compression or capsule filling. This improves content uniformity, flow, and density.

Single-Pot Processing: Mixing, granulation, and wet massing in one place reduces material handling, time, and contamination risk.

Better Control: Precise control over impeller/chopper speed and liquid addition rate leads to consistent granule quality.

Efficiency: Faster processing and reduced solvent/binder usage.

Reproducibility: Critical for regulatory compliance (GMP).

Yes, an RMG is essentially a high-shear granulator. The high-speed impeller and chopper impart significant shear force, producing dense, spherical granules.

Impeller Speed: Affects mixing efficiency and granule density.

Chopper Speed: Controls lump breaking and granule size distribution.

Binder Addition Rate & Method: Spray rate and nozzle position affect uniformity.

Mixing & Massing Time: Under- or over-massing can lead to poor granules.

Product Temperature: Can rise due to shear; needs monitoring.

The point where optimal granule characteristics are achieved. It’s determined by empirical observation (e.g., consistency) or, more scientifically, by monitoring power consumption/amperage of the impeller motor or torque. A sharp rise indicates the desired endpoint.

Yes. Excessive mixing time (over-massing) after liquid addition can lead to too hard or too dense granules, which may cause capping, lamination, or poor disintegration in the final tablet.

Top-Driven: The motor is above the bowl. Easier maintenance, no risk of lubrication leakage into the product, but can have larger footprints.

Bottom-Driven: The motor is below the bowl. More stable drive, easier bowl handling/tipping, but requires superior seals to prevent product contamination from the gearbox.

Stainless Steel 316L is standard for pharmaceutical use. Contact surfaces are polished to a pharmaceutical finish (e.g., Ra < 0.4 µm) for easy cleaning and preventing material adhesion.

User Requirements Specification (URS), Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ), Standard Operating Procedures (SOPs), maintenance logs, and cleaning records.

WhatsApp us

Holds the powder blend and facilitates mixing/granulation.

Mixing Bowl (Vessel)