Vacuum Emulsifying Mixer for Creams & Lotions

A vacuum emulsifying mixer is a key machine used in the cosmetic industry for producing creams, lotions, and other emulsion-based products.

Learn More About Our Vacuum Emulsifying Mixing Equipment

The vacuum emulsifying mixing equipment combines mixing, homogenizing, and deaeration under vacuum conditions to ensure a smooth, stable, and air-free final material. We offer varying capacities of 20-90 L, 100 L, 200 L, and 500 L options.

Volume: 20 L – 100 L

Emulsifying motor: 1.1 kW- 3 kW

Height: 1,700-2,600

Volume: 100 L

Emulsifying motor: 3 kW

Height: 2,800

Volume: 200 L

Emulsifying motor: 4 kW

Height: 3,100

Specification

| Model | 20L | 50L | 100L | 200L | 500L |

|---|---|---|---|---|---|

| Volume | 20L | 50L | 100L | 200L | 500L |

| Emulsify motor | 1.5KW (0-3500rpm/min) | 3KW (0-3500rpm/min) | 3KW (0-3500rpm/min) | 4KW (0-3500rpm/min) | 7.5KW (0-3500rpm/min) |

| Mixer power | 0.75KW 0-60r/m | 0.75KW 0-60r/m | 1.5KW 0-60r/m | 1.5KW 0-60r/m | 2.2KW 0-60r/m |

| Lengt | 1500 | 2750 | 2800 | 2850 | 3800 |

| widthme | 800 | 2400 | 2150 | 2200 | 2800 |

| height | 1500 | 1900 | 2100 | 2200 | 2700 |

| Max height | 2050 | 2600 | 2800 | 3100 | 3950 |

Applicable Products

Learn more about our vacuum emulsifying mixers

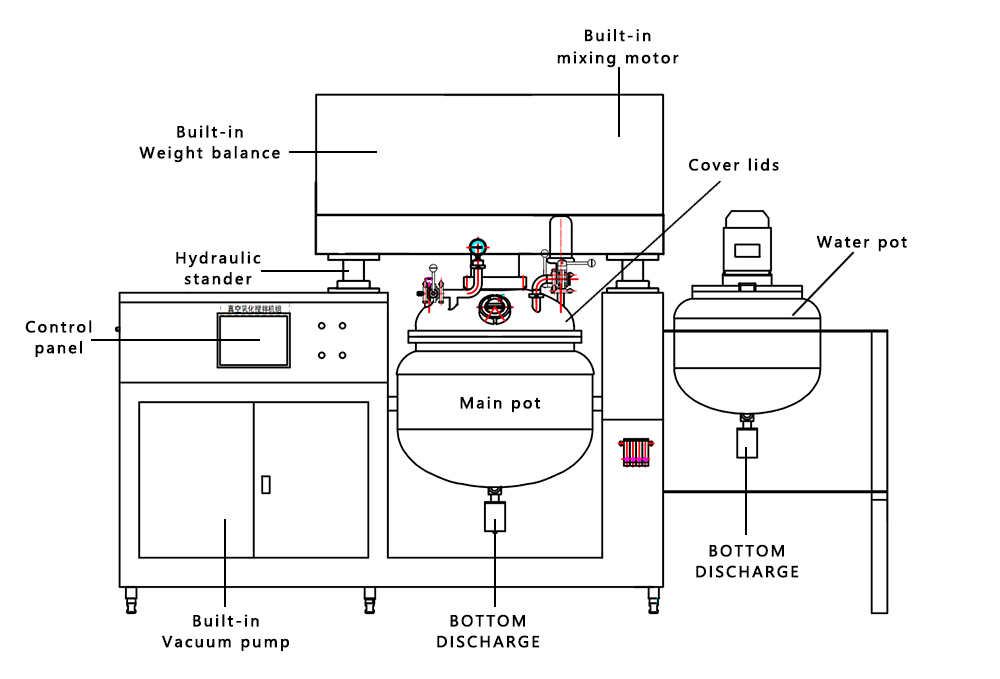

Key Parts of the Vacuum Emulsifying Mixer

The PTFE-coated scraper with spring-loaded edge maintains a ≤2 mm wall clearance and has a variable speed of 15-45 RPM.

Anchor Agitator

Oil-sealed rotary vane pump (-0.098 MPa) with a condenser trap and auto defoaming via a PID-controlled vacuum gradient.

Vacuum System

10 touchscreen with SCADA interface, stores 100+ formulas, supports OPC-UA for MES integration.

HMI Control PanelHow Does Vacuum Emulsifying Mixers Work

- Step 1. Raw Material Heating: Oil-based and water-based ingredients are separately heated to 60-85°C in a double-jacketed tank to completely melt solid components.

- Step 2. High-Speed Homogenization: A high-shear homogenizer operates at 3,000-6,000 RPM to vigorously break down oil-water particles, creating a fine emulsion.

- Step 3.Slow-Speed Mixing: An anchor stirrer simultaneously rotates at 20-60 RPM to prevent sedimentation and ensure even heat distribution.

- Step 4. Vacuum Deaeration: A vacuum pump operates at -0.08 to -0.1 MPa to completely remove air bubbles and prevent product oxidation

- Step 5.Cooling & Setting: The emulsion is cooled to 20-40°C under continuous stirring before adding heat-sensitive ingredients like fragrances.

- Step 6. Finished Product Discharge: The bubble-free, silky-smooth final product is discharged through a bottom valve for direct packaging.

FAQ

It can handle creams, lotions, serums, and high-viscosity formulas (up to 1,000,000 cP) with oil/water phase compatibility.

Yes, full CIP/SIP (Clean-in-Place/Sterilize-in-Place) with 3D spray balls and FDA-compliant seals.

Our 3-in-1 homogenization operation (shear/emulsify/vacuum) reduces processing time by 40% versus conventional mixers.

Cosmetics (creams, lotions, shampoos)

Pharmaceuticals (ointments, gels, syrups)

Food products (mayonnaise, sauces, dressings)

Chemicals (paints, adhesives, lubricants)

Removes air bubbles → Smoother texture

Prevents oxidation → Longer shelf life

Enhances mixing efficiency → Better product consistency

Homogenizer = Breaks particles into smaller sizes (for uniformity).

Emulsifier = Combines immiscible liquids (oil & water) into a stable emulsion.

A vacuum emulsifying mixer does both, under a vacuum.

Consider:

Capacity (lab-scale, pilot, or industrial)

Material (SS304/SS316 for food/pharma)

Vacuum level (adjustable for different products)

Shear speed (higher RPM = finer emulsion)

Automation (manual vs. PLC control)

Manual cleaning (disassemble & wash parts)

CIP (Clean-in-Place) (automated cleaning without disassembly)

Yes! Models with strong motors & robust agitators can mix:

Thick creams

Ointments

Pastes

316L stainless steel jacketed vessel with mirror polishing (Ra ≤0.4 μm), rated for -0.1 MPa - 0.5 MPa pressure.

Vacuum Emulsification Vessel