TOP 10 Tablet Coating Machine Manufacturers In The World(2026 Reviews)

Making medicines needs special machines for many jobs. Coating tablets is a key step that helps drugs work well and

Tablet coating machine is an industrial device used to apply a uniform, thin layer of coating material onto the surface of solid dosage forms (like tablets, pellets, granules, or capsules) or other particles. The primary goals are to improve appearance, mask taste/odor, control drug release, protect ingredients, or add functionality.

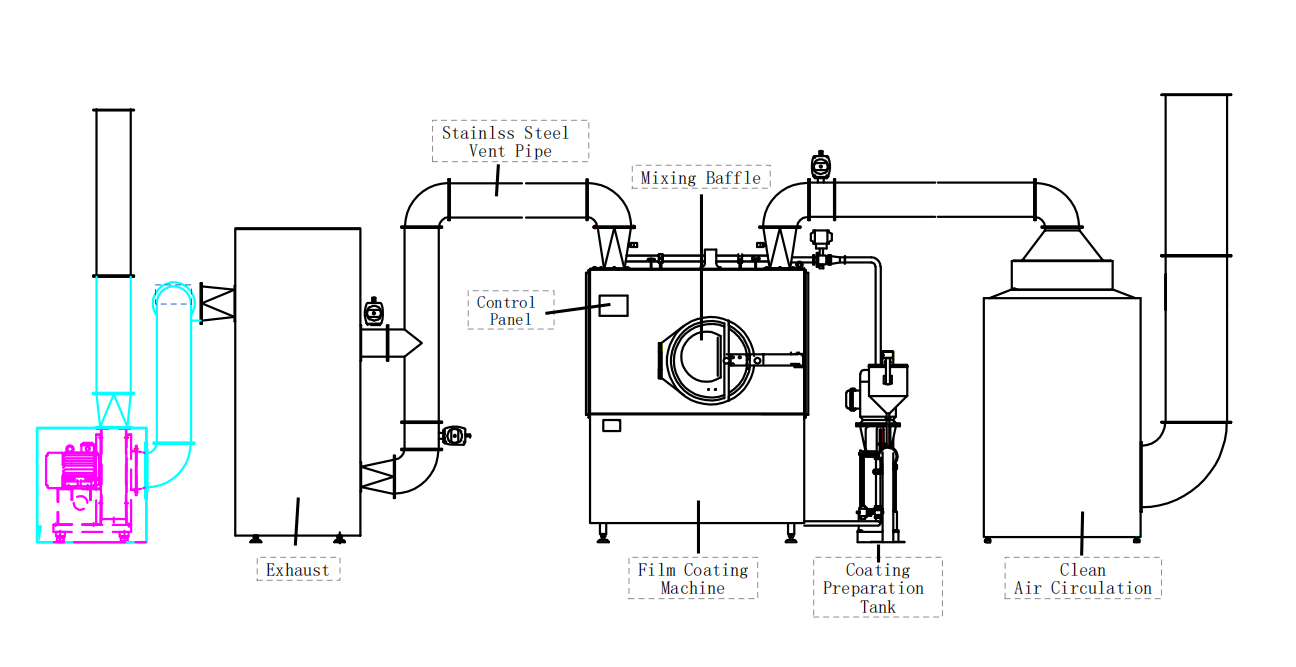

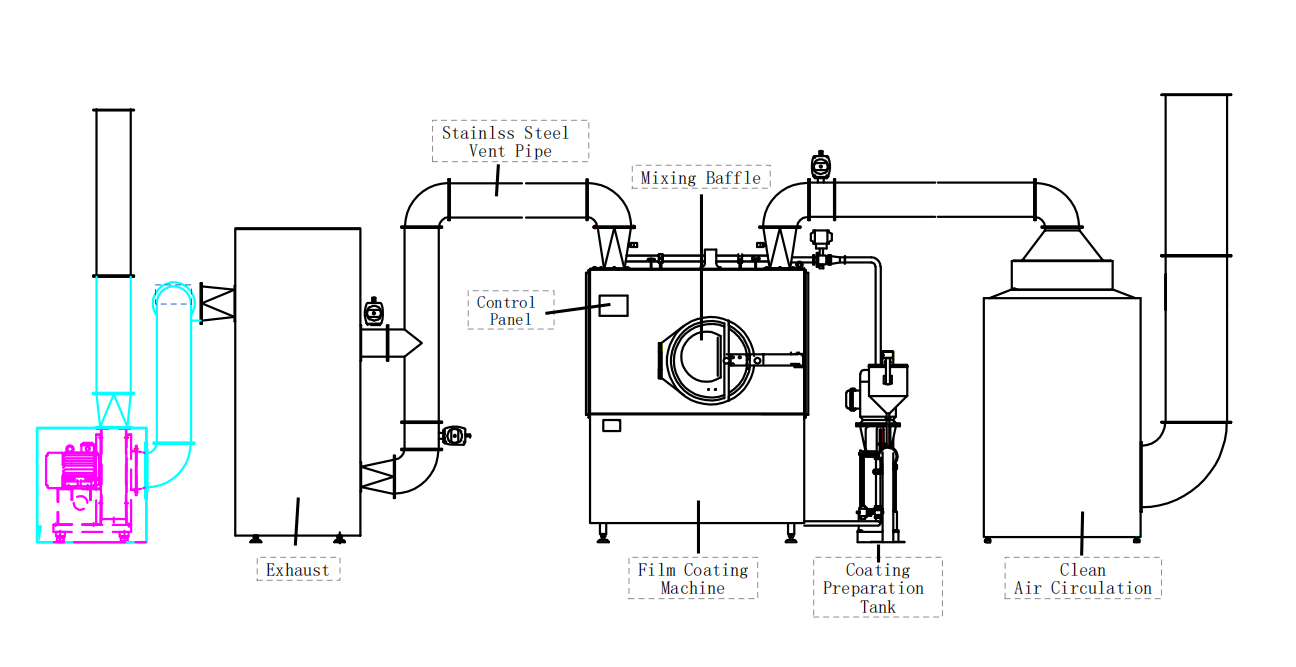

The coating process is dust- and slurry-free, which improves the working environment and reduces cross-contamination of tablets. The tablet coating process is simple, greatly reducing coating time and improving production efficiency.

Rotating Speed of Coating Pan: 1-19 RPM

Load Capacity: 80 L

Weight: 684 kg

Rotating Speed of Coating Pan: 1-16 RPM

Load Capacity: 150 L

Weight: 1,020 kg

Rotating Speed of Coating Pan: 1-16 RPM

Load Capacity: 260 L

Weight: 1,300 kg

| Model | BG1000E | BG600E | BG400E | BG260E | BG150E | BG80E | BG40E | BG10E | |

|---|---|---|---|---|---|---|---|---|---|

| Load Capacity(L) | 1000 | 600 | 400 | 260 | 150 | 80 | 40 | 10 | |

| Coating Pan Speed | 12(rpm) | 1-12(rpm) | 1-13(rpm) | 1-16(rpm) | 1-16(rpm) | 1-19(rpm) | 1-21(rpm) | 1-25(rpm) | |

| Main Motor Power (kW) | 7.5 | 5.5 | 3 | 2.2 | 2.2 | 1.5 | 1.1 | 0.55 | |

| Coating Pan Diameter(mm) | 1580 | 1580mm | 1580mm | 1360mm | 1200mm | $930mm | 750mm | 500mm | |

| Motor Power of Air Exhaust Cabinet(kW) | 22 | 11 | 7.5 | 5.5 | 5.5 | 3 | 2.2 | 0.75 | |

| Air Exhaust Flow(m3/h) | 20000 | 15450 | 10000 | 7419 | 7419 | 5268 | 3517 | 1285 | |

| Motor Power of Hot Air Cabinet | 7.5 | 5.5 | 3 | 2.2 | 1.5 | 1.1 | 0.75 | 0.37 | |

| Air Flow of Hot Air Cabinet (m3/h) | 10000 | 7419 | 5200 | 3517 | 2356 | 1685 | 1285 | 816 | |

| Machine Weight (kg) | 4000 | 2800 | 1562 | 1300 | 1020 | 684 | 500 | 200 | |

| Clean Air | Pressure (Mpa) | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 |

| Air Consumption(m3/min) | 3.5 | 2 | 1.5 | 1.2 | 1 | 0.4 | 0.4 | 0.3 | |

| Dimensions (mm) | Main Machine | 2500×3100×2800 | 2000×2277×2660 | 2000×167×2660 | 1730×1440X2470 | 1570X1280×2250 | 1210×10000X1900 | 1000×800×1900 | 900×620×1800 |

| Hot Air Cabinet | 1700×1200×2600 | 1600×1100×2350 | 1000×x900×2300 | 1000x900×2300 | 1000x900×2300 | 900×800×22050 | 900×800×2050 | 800×650×1600 | |

| Air Exhaust Cabinet | 3000×1115×2400 | 1050×1000×2470 | 1050×1050×233 | 1050×1060×2300 | 950×950×2245 | 900×820×2130 | 820×720×1750 | 800×650×1600 | |

| Steam Heating Power(kW) | 40 | 29 | 18 | 14 | 14 | 10 | 9 | 9 | |

| Electric Heating Power(kW) | 120 | 79 | 61 | 48 | 42 | 30 | 24 | 12 |

Allows you to easily adjust air pressure, temperature, and atomization function options.

Simplified Operation Panel

The high quality of our tablet coating machines comes from our technicians’ experience and focus on every detail.

Built by Experienced TechniciansThis includes various mixing methods for powder mixers, standard operating procedures (SOPs) for maintenance, and a list of recommended suppliers, etc.

Making medicines needs special machines for many jobs. Coating tablets is a key step that helps drugs work well and

Tablet coating may look simple on the surface, but anyone in pharma manufacturing knows it’s where things usually go wrong.

A tablet coating machine helps protect tablets and makes them easier to swallow and store. Using it the right way

Have you ever wondered how pills get their smooth, colorful outer layer? The answer lies in a fascinating piece of

Yep, sure!!!

A tablet coating machine applies a thin, uniform layer of coating material onto tablet cores. Key purposes include:

Taste masking (bitter APIs)

Moisture protection (hygroscopic materials)

Light protection (photosensitive drugs)

Controlled release (enteric, sustained-release coatings)

Identification (brand colors, markings)

Swallowability improvement (smooth surface)

Mechanical protection (reduce chipping/dusting)

Standard Pan Coaters: Conventional coating pans (angled, rotating)

Perforated Pan Coaters:

Accela-Cota™: Baffled pan with perforations

Driacoater™: Fully perforated drum

Hi-Coater™: Angled perforated pan

Fluid Bed Coaters: Wurster bottom-spray systems for pellets

Continuous Coaters: For high-throughput production

| Sugar Coating | Film Coating |

|---|---|

| Thick coating (30-50% weight gain) | Thin coating (2-5% weight gain) |

| Multiple layers (subcoat, smoothing, coloring, polishing) | Single polymer layer |

| Long process time (hours/days) | Short process time (1-3 hours) |

| Requires skilled operators | Automated, reproducible |

| Uses sucrose-based solutions | Uses polymer solutions (HPMC, PVP, etc.) |

| Rounded, glossy appearance | Retains tablet shape, smooth finish |

Coating Pan: Rotating drum (perforated or solid)

Spray System:

Guns/Nozzles: Typically pneumatic or airless

Pump: Peristaltic or piston pumps for coating solution

Air Supply: Atomizing and pattern air

Air Handling System:

Inlet Air: Heated, filtered air supply

Exhaust Air: Removal of solvents/moisture

Control System: PLC/HMI for parameter control

Dust Collection: Filters to recover fines

Discharge System: For coated tablets

Baffles are angled plates inside the coating pan that:

Improve tablet mixing and uniformity

Prevent tablet sliding (promote cascading motion)

Enhance drying efficiency by exposing all tablets to air

Reduce tablet-to-tablet impact (minimize attrition)

Spray Rate: Volume of coating solution per minute

Atomizing Air Pressure: Creates droplet size (typically 1-3 bar)

Pattern Air Pressure: Controls spray shape/flattening

Inlet Air Temperature: Typically 40-70°C (depends on coating type)

Bed Temperature: Key indicator (usually 30-45°C)

Pan Speed: RPM (affects mixing and attrition)

Exhaust Air Temperature/RH: Indicates drying efficiency

Gun-to-Bed Distance: Typically 6-12 inches

Preheating: Warm tablets and equipment

Spraying: Apply coating solution in multiple passes

Drying: Evaporate solvent between spray cycles

Sealing: Initial moisture barrier (for hygroscopic cores)

Color Coating: Main coating layer(s)

Polishing: Final glossy layer (if required)

Cooling: Before discharge

Unloading: Through discharge port

Proper tablet mixing (correct pan speed/baffle design)

Optimized spray pattern (overlap, coverage)

Consistent droplet size (proper atomization)

Adequate drying between spray passes

Weight gain monitoring during process

Immediate Release: HPMC, PVP, PEG-based

Enteric Coatings: Cellulose acetate phthalate (CAP), HPMC phthalate, Eudragit® L/S

Sustained Release: Ethyl cellulose, Eudragit® RL/RS

Aqueous vs. Organic: Water-based (common) or solvent-based (for moisture-sensitive APIs)

Inspect daily: For wear, clogging, or damage

Clean after each batch: Prevent buildup

Replace when:

Wear affects spray pattern

Droplet size becomes inconsistent

Visible damage/corrosion

Every 6-12 months (preventive)

| Aqueous Coating | Organic Solvent Coating |

|---|---|

| Water-based solutions | Alcohol, acetone, or other solvents |

| Safer (non-flammable) | Fire/explosion hazards |

| Environmentally friendly | Solvent recovery needed |

| Slower drying | Faster drying |

| Suitable for most drugs | For moisture-sensitive APIs |

| Now industry standard | Declining use due to regulations |

Weight gain (2-5% typical for film coating)

Coating uniformity (color, thickness)

Dissolution profile (for functional coatings)

Appearance (smoothness, gloss)

Friability (post-coating)

Moisture content

Taste masking efficiency

WhatsApp us

We have various types of coating pans, all made of 316L stainless steel.

316L Coating Pan